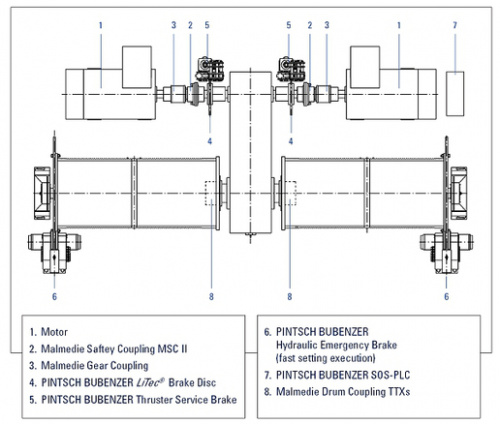

Snag Overload System (SOS)

Snag load protection system for container cranes.

It

eliminates the danger of structural damage starting at the motor, which

is beside the brake disc the major source of snag inertia load.

At any kind of overload the inertia and the driving force of the (AC!) motor is separated from the hoist by the MSCII within one millisecond. To reduce the remaining inertia coming from the brake disc, Pintsch Bubenzer LiTec® brake discs offering 60% less inertia than steel discs are in use.

The special designed PINTSCH BUBENZER service

and emergency brakes (fast setting execution) avoid at the same time a

reverse of the rope drum. The reaction time of the system in combination

with its own and separate PLC is ultra fast and completed, before

conventional hydraulic systems are able to react.??Beside the advantage

of having even less maximum rope forces compared to a conventional snag

system, the system is much less in weight, low maintenance and cost

effective.

Downloads

-

Snag overload system (SOS)

(4677 KB)

Snag overload system (SOS)

(4677 KB)

Options

- Automatic rope release after snag fall

- Display in the crane operator's cabin

- Automatic reset of the coupling after the snag fall

Single-Rope-Protection (SRP)

In

addition and independent of the mechanical protection, the system is

equipped with a so called Single-Rope-Protection (SRP). A second channel

of the (usually mounted) load cells is used to permanently monitor the

loads of each single wire rope ultra-fast. In case of overload of only

one wire rope, the SOS-PLC closes the emergency brakes and the coupling

will trip (speed dependent). By this, the development of Snag situations

is detected even faster and on top, the system is redundant.

Another advantage of the Single-Rope-Protection: At empty

spreader operation (detected by using the twistlock signals), the

trigger point is set to an even lower value, because the max. rope loads

are much less on empty spreader operation compared to load operation.

Result: Even earlier and faster protection in Snag situations with empty

spreader!?

Advantages

In addition to the advantage that less high rope forces occur with this system than with conventional hydraulic protection systems, the system is lighter, requires less maintenance and is cost-effective.

When operating with an empty spreader (recognisable via the processing of the twistlock signals), the protection point is lowered further, as the max. rope loads with an empty spreader are considerably lower than with a load.

Result: The protective effect starts even earlier in the case of snag with an empty spreader!

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de