LüCo TensionPro2©

Acoustic measuring device for belt tension

Precise pre-tensioning favours the service life of the belt drive and prevents overloading of the drive components.

Professional belt tension check

Only a perfectly adjusted belt drive can achieve efficient performance. If the belt tension is too high, the bearings are subject to increased wear. If the drive belt tension is too low, the required power cannot be transmitted, the belt can overheat and wear out very quickly.

Accurately measuring and adjusting the belt tension extends the service life of the pulleys, belts, bearings and seals in the long term and prevents vibrations and overloading of the drive.

We generally recommend investing in professional measurement technology, especially when using higher-quality industrial belts. The use of a tensiometer, trummeter or belt tension tester increases the efficiency of the belt drive and reduces wear and energy costs at the same time. The belt tension tester therefore pays for itself within just a few months.

In general, there are various methods of measuring the belt tension of a drive belt:

- Force / deflection

- Optical vibration measurement

- Acoustic vibration measuremen

Downloads

-

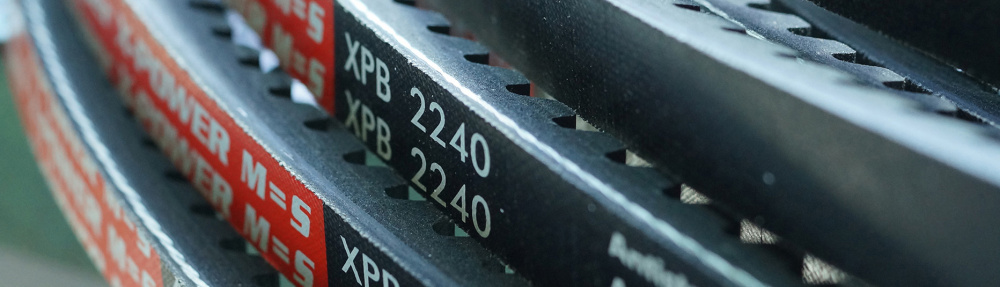

Measurement technology for drive belts

(2985 KB)

Measurement technology for drive belts

(2985 KB)

-

Operating instructions LüCo TensionPro2

(1857 KB)

Operating instructions LüCo TensionPro2

(1857 KB)

Your benefits

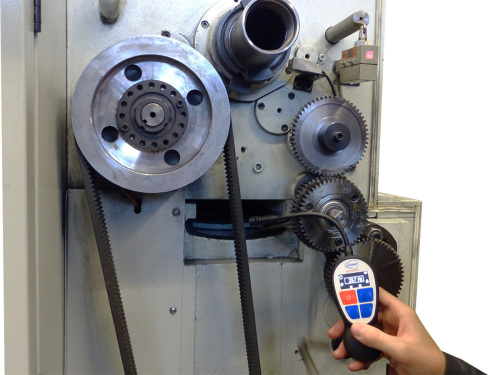

- Non-contact, acoustic measuring technology

- Highly sensitive sensor for precise measurement of belt tension

- Suitable for all belt and tension member types

- Small sensor head on the flexible gooseneck for measurements even in hard-to-reach places

- Ergonomic shape for optimum one-handed use

- Integrated, rechargeable lithium polymer battery

- Additional functions via app use

- Measuring range: 10 - 600 Hz

- Measuring accuracy: 10 - 400 Hz: ± 1%, 400 - 600 Hz: ± 2%

LüCo TensionPro2©

The LüCo TensionPro2© makes it possible to set the appropriate belt tension quickly, easily and precisely. The fully electronic belt tension measuring device is equipped with the latest microprocessor technology and can be used for V-belts, timing belts and power transmission belts. Reliable measurement results are achieved regardless of the type and condition of the drive belt.

The acoustic measuring principle is utilised: A pulse is transmitted to the belt. This initially vibrates in all vibration modes. However, the high-frequency vibrations decay faster than the fundamental vibration. The vibration frequency of the fundamental vibration is in a fixed relationship with the belt pre-tension: the higher the frequency, the higher the belt pre-tension.

Analogue tension checker

The Tension Tester is a simple but effective measuring device for

measuring pre-tension. There are two O-rings at the top and bottom of the

measuring device. The top O-ring on the measuring device for the force is set

to 0, the bottom O-ring on the measuring device for the deflection and is set

to a calculated value. Now the belt is deflected in the middle with the

measuring device until the lower O-ring is at the same height as another belt

or a ruler laid across the two pulleys. The required force can now be read on

the upper O-ring. According to the specifications from the drive calculation,

the drive can now be tightened or loosened.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de