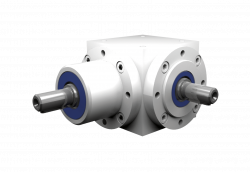

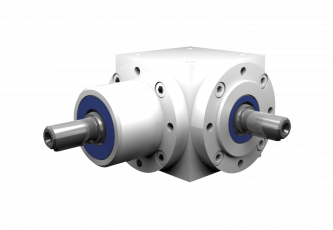

Bevel gearboxes and geared motors

A bevel gear enables the transmission to be either slow or fast. The axes cross in the gearbox at an angle of 90°. The size of the gearbox reflects the length of the housing (example V 120 – housing length 120 mm).

Bevel

gears are high-precision and powerful torque converters. These high-performance

gearboxes are up to todays high demands in every respect, they are compact and

impact resistant. It is not without good reason that they are used worldwide in

all industrial branches of mechanical and plant engineering. Bevel gears are

also known colloquially as bevel gears, axle gears, gear wheels or step-down

and step-up gears.

Downloads

-

Bevel gearboxes typ V, VS, VL

(6448 KB)

Bevel gearboxes typ V, VS, VL

(6448 KB)

-

Multi shaft bevel gearboxes

(1808 KB)

Multi shaft bevel gearboxes

(1808 KB)

-

Gearbox motors

(3137 KB)

Gearbox motors

(3137 KB)

Short info

- Robust, powerful, compact

- Cast iron or steel body

- Spiral toothed wheel sets

- Maintenance free

Markets

- Automation

- Transfer case

- Packaging machines

- Linear technology

- Machine building

and plant construction

Whether application-specific drive solutions for the construction of

special machines or a series products for general mechanical engineering: the

modular system offers a wide range of drive solutions of the highest product

and process quality at a competitive price/performance ratio.

Produktübersicht

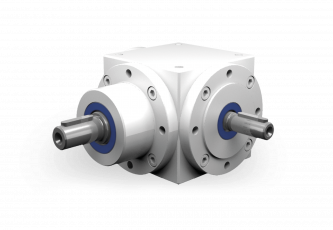

Type V – Standard bevel gearboxes

- Gear ratios: i =

1:1 to 6:1

- Maximum output

torque: 5400 Nm

- 9 gearbox sizes

with edge lengths of 065 to 350 mm

- Low-backlash

construction < 6 angular minutes possible

- Housing made of

grey cast iron or steel

Type VS – Type V with step-up ratio

- Gear ratios: i = 1:1.5 and 1:2

- Maximum output torque: 1200 Nm

- 6 gearbox sizes with edge lengths of 090 to 260 mm

- Low-backlash construction < 10 angular minutes possible

- Larger shaft diameter (N2), slowly rotating

- Housing made of grey cast iron or steel

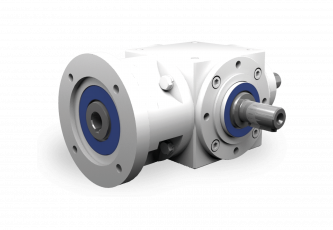

Type VL – Type V with flange

- Gear ratios: i = 1:1 to 6:1

- Maximum output torque: 2310 Nm

- 8 gearbox sizes with edge lengths of 065 to 260 mm

- Low-backlash construction < 6 angular minutes possible

- Suitable for fitting IEC standard motors

- Drive side with hollow shaft and flange

- Housing made of grey cast iron or steel

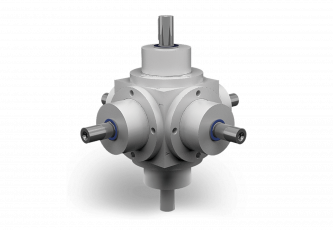

Multi shaft gearbox – with additional shafts

- For gear ratios of 1.5:1 to 6:1 with type V

- For gear ratios of 1.5:1 to 2:1 with type VS

- With solid shaft or hollow shaft

- Up to 6 shaft ends

Type VLM – Bevel gear motor

- Gear ratios: i = 1:1 to 6:1

- Maximum output torque: 2310 Nm

- 8 gearbox sizes with edge lengths of 065 to 260 mm

- Low-backlash construction < 6 angular minutes possible

- With mounted IEC standard motor

- Housing made

of grey cast iron

Technical data

Type V

| Characteristic | Standard |

|---|---|

| Teeth | Spiral toothed bevel gear set |

| Gear ratio | 1:1 bis 3:1 (V065), to 6:1 (from V090) |

| Housing / Flanges | Grey cast iron, steel |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges. |

| Shaft | Material 1 C45, shaft ends with ISO 6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shafts end with ISO 7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the fi rst 500 service hours and then every 5000 service hours. |

| Lubricant | Synthetic lubricants |

Type VS

| Characteristic | Standard |

|---|---|

| Teeth | Spiral toothed bevel gear set |

| Gear ratio | 1,5:1 to 2:1 |

| Housing / Flanges | Grey cast iron, steel |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges |

| Shaft | Material 1 C45, shaft end fit ISO 6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Not available |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the fi rst 500 service hours and then every 5000 service hours.g der Öltemperatur von < 90°C nicht erforderlich. Die Lebensdauer der Lager kann um den Faktor 1,5 gesteigert werden, wenn nach den ersten 500 Betriebsstunden und dann alle 5000 Betriebsstunden ein Ölwechsel erfolgt. |

| Lubricant | Synthetic lubricants |

Type VL

| Characteristic | Standard |

|---|---|

| Teeth | Spiral toothed bevel gear set |

| Gear ratio | 1:1 to 3:1 (VL065), to 6:1 (from VL090) ) |

| Housing / Flanges | Grey cast iron |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges. |

| Shaft | Material 1 C45, shaft end fit ISO 6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shaft end fit ISO 7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the first 500 service hours and then every 5000 service hours. |

| Lubricant | Synthetic lubricants |

| Flange | Suited for the mounting of IEC motors |

| Coupling | Three-piece claw coupling |

Type VLM

| Characteristic | Standard |

|---|---|

| Teeth | Spiral toothed bevel gear set |

| Gear ratio | 1:1 bis 3:1 (to VLM065), to 6:1 (from VLM090) |

| Housing / Flanges | Grey cast iron |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges |

| Shaft | Material 1 C45, shaft ends greased Fit with ISO 6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shaft end fit ISO 7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the fi rst 500 service hours and then every 5000 service hours |

| Lubricant | Synthetic lubricants |

| Motor | IEC standard motor P>0,75kW; Efficiency class IE3 |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de