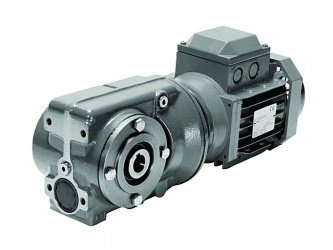

Worm gearboxes and motors

Worm gears are helical gears and where the rotary motion of a worm gear on a cylindrical shaft is transmitted to a rotating gear wheel that is offset by 90°. These gears allow a particularly high gear ratios in a confined spaces and are therefore ideal for use in tight spaces.

The worm gear consists of two components: a threaded worm shaft and a threaded worm wheel. The worm shaft is usually made of steel and the worm wheel is usually made of bronze.

Worm gears are high-precision and very strong offset gears. They are mainly used when a large overall gear ratio is required. With a worm gear and worm wheel, a large overall ratio can be achieved with fewer steps. This means that a smaller, less expensive gearboxes can be used.

These high-performance gears meet our requirements every time and in every respect and are used in demanding applications such as conveyor systems, mills and bucket elevators, extrusion machines, machine tools or separating machines.

Downloads

-

Schneckengetriebe

(1181 KB)

Schneckengetriebe

(1181 KB)

Short info

- High ratio in one gear reduction

- Compact design with angled output

- High-precision, high-performance operation

- Smooth operation

- Low running noise

- High overload capacity

- Robust, insensitive construction

- Self-locking possible

- Hollow shaft

version possible

Series C - Helical worm geared motor

- Gear ratios: i=8:1 to 16.000:1

- Maximum output torque 10.000 Nm

- 8 unit sizes from centre distance from a= 5,3 to 65 mm

- Compact aluminium housing

- Flanges from 63 to 225

Series AJ - Junior worm gear

- Gear ratios: i=5:1 to 70:1

- Maximum output torque 950 Nm

- 6 unit sizes from centre distance from a= 028 to 86 mm

- Grey cast iron housing

- Suitable for mounting IEC standard motors (63 to 132)

- Suitable for mounting NEMA standard motors (56 to 215)

- Designed with hollow output shafts

- Lubricated for life

Series BS - Compact worm gear

- Gear ratios: i=6,67:1 to 104:1 (ohne Vorstufe)

- Maximum output torque 310 Nm

- 4 unit sizes from centre distance a= 40 to 71 mm

- Aluminium housing

- Suitable for mounting IEC standard motors (63 to 132)

- Lubricated for life

Series AM - Mid worm gear

- Gear ratios: i=5:1 to 70:1

- Maximum output torque 8.500 Nm

- 4 unit sizes from centre distance from a= 100 to 200 mm

- Grey cast iron housing

- Suitable for mounting IEC standard motors (63 to 132)

- Suitable for mounting NEMA standard motors (56 to 215)

- Designed with hollow outlet hole

Series ER - Heavy duty worm gear

- Gear ratios: i= 5:1 to 4900:1

- Maximum output torque 31.000 Nm

- 4 unit sizes from centre distance from a= 254 to 432 mm

- Grey cast iron housing

- With motor mounting adapter and flexible input coupling

Whether application-specific drive solutions for the construction of

special machines or series products for general mechanical engineering: the

modular system offers a wide range of drive solutions of the highest product

and process quality at a competitive price/performance ratio.

Technical data

Types AJ 0280 | AJ 0410 | AJ 0510 | AJ 0610 | AJ 0730 | AJ 0860

| Eigenschaft | Standard |

|---|---|

| Housing / gearing | Cast iron housing, bronze worm wheel, hardened and ground worm shaft |

| Gear ratios | i = 5:1 to 70:1 in single stage, to 4900:1 in double reduction |

| Output torque | Up to 31.000 Nm (275000 lb.in.) |

| Input Power | Up to 320 kW (430 PS) |

| Motor attachment | With motor mounting adapter and flexible input coupling |

Types AM 1002 | AM 1252 | AM 1602 | AM 2002

| Eigenschaft | Standard |

|---|---|

| Housing / gearing | Cast iron housing, bronze worm wheel, hardened and ground worm shaft |

| Gear ratios | i = 5:1 bis 70:1 in single stage, bis 4900:1 in double reduction |

| Output torque | Up to 8500 Nm (68000 lb.in.) |

| Input Power | Up to 100kW (132 PS) |

| Mounting threaded hole | Designed with hollow outlet bore. Output shaft can be mounted. |

| Motor attachment | IEC-frames from 80 to 132, NEMA-frames from 56 to 256 |

Types ER 10 | ER 12 | ER 14 | ER 17

| Eigenschaft | Standard |

|---|---|

| Housing / gearing | Cast iron housing, bronze worm wheel, hardened and ground worm shaft |

| Gear ratios | i = 5:1 bis 70:1 in single stage, bis 4900:1 in double reduction |

| Output torque | Up to 950 Nm (7600 lb.in.) |

| Input Power | Up to 12 kW (16 PS) |

| Mounting threaded hole | Designed with hollow output shafts. Extended double output shafts available. |

| Motor sizes | IEC-frames from 63 to 132, NEMA-frames from 56 to 215 |

| Atex-compliant | Can be supplied against Group 2 or 3 for surface industries at designated explosion sites, Zones 1 and 2 for gases, vapours and mists and Zones 21 and 22 for dust. |

Types C0321 | C0421 | C0521 | C0621 | C0721 | C0821 | C0921 | C1021

| Eigenschaft | Standard |

|---|---|

| Housing / gearing | Cast iron housing, bronze worm wheel, hardened and ground worm shaft |

| Gear ratios | i = 8:1 to 250:1 in double reduction and 16000:1 in combined units |

| Output torque | Up to 10.000 Nm (88.500 lb.in) |

| Input Power | Up to 45kW (60PS) |

| Motor sizes | IEC-frames from 63 to 225; NEMA frames from 56 to 326 |

| Options | Can be supplied as double, triple, quadruple and quintuple reduction units in flange or foot or shaft mount execution. Available as motorised, motor ready (to accept clients own IEC/ NEMA motor) or as a reducer with a keyed input shaft. |

Types BS40 | BS 50 | BS63 | BS71

| Eigenschaft | Standard |

|---|---|

| Housing / gearing | Aluminium housing, bronze worm wheel, hardened and ground worm shaft |

| Gear ratios | i = 6,67:1 bis 104:1 (without pre-step) |

| Output torque | Up to 310 Nm (2800 lb.in.) |

| Input Power | Solid shaft, IEC Flange and Servo |

| Output options | Solid shaft, IEC Flange and Servo |

| Atex-compliant | Can be supplied against Group 2 or 3 for surface industries at designated explosion sites, Zones 1 and 2 for gases, vapours and mists and Zones 21 and 22 for dust. |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de