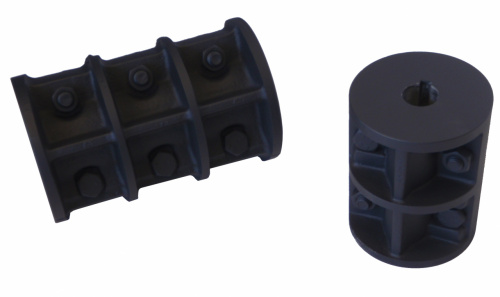

Clamp coupling DIN115

The clamp coupling according to DIN115 is a torsionally rigid

shaft connection with various advantages. The coupling can absorb impacts and

radial or axial loads exceptionally well. The coupled shafts are always in

exact aligned. The radially screwed coupling ensures easy assembly. The shells

are perfectly aligned with each other to ensuring a safe and secure screwed connection. Due to

the slitting of the coupling, the application is ideal for shafts connected in

series (e.g. transmission shafts).

When

coupling shafts have different diameters, we recommend that the thicker shaft

end be machined down to the diameter of the smaller one. If this is not

possible, the version corresponding to the larger shaft diameter is used with a

stepped bore. (Form B).

The vibration

caused by the material wear is kept within permissible limits, as is the wear

(abrasion) caused by the sliding movement. Due to the absolutely identical

coupling halves, the forces resulting from the torque are absorbed by both of

the soft material rings, which is thus the reason for the good torsional

elastic and flexible properties of the double-flex coupling.

Unless otherwise specified in the order, the double-flex couplings are drilled according to ISO H7. Grooves for parallel keys DIN 6885-1 or tapered wedges DIN 6886.

Shortinfo

- Good mountability

- Damping due to cast material

- Material GJL-250 or steel

- Finish bored with keyway according to DIN 6885/1

Available versions

Horizontal arrangement

- Form A for shaft ends with the same diameter (available at short notice)

- Form B for shaft ends with different diameters

Vertical arrangement

- Form C with axial thrust washers according to DIN 28135

Design and calculation

We will be happy to assist you with the selection of the coupling. Information on assembly, disassembly and technical data can also be found in our catalogue for download.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel