Subcontract balancing

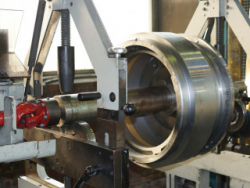

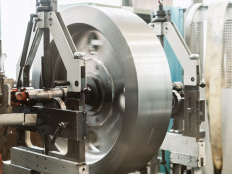

State-of-the-art computer-controlled balancing machines from Schenck can

be used to balance rotationally symmetrical workpieces in one or two planes

according to DIN ISO 21940 in quality grades G16, G6.3 or G2.5. The aim is to

achieve the optimal smooth running together with the maximum performance and

absolute precision. The balancing quality and the measured residual unbalance

are documented and, upon request can be recorded and certified according to DIN EN 10204. Standard drive elements, which are purchased

from Asia with a balancing quality of G16, can also be rebalanced to a higher

quality level at the customer's request.

In addition to balancing drive elements

from our own production, we also offer contract balancing of customer-specific

components. For this purposewe have a large selection of balancing fixtures

available for a wide range of requirements.

Downloads

-

FLOHR Machine Overview

(771 KB)

FLOHR Machine Overview

(771 KB)

Excerpt machine overview

| Type | Manufacturer | Max. Ø | Max. weight | Procedure |

|---|---|---|---|---|

| H 3 U | Schenck | 800 mm | 300 kg | Dynamic balance bench |

| 130 HBA-BAE 0714 | Schenck | 800 mm | 500 kg | Vertical balancing machine |

| H 5 U | Schenck | 2500 mm | 5500 kg | Dynamic balance bench |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel