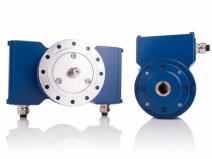

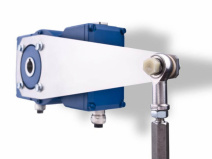

FG 40 / FGH(J) 40

Short info: Incremental encoders

- Hollow shafts up to Ø 25 mm

- Solid shafts up to Ø 14 mm (flange or foot mounting)

- Robust design, other encoder can be attached

- Up to 1 million pulses HTL / TTL, up to 2500 sine periods

- Options: Second signal output, FOC transmitter, programmable overspeed switches, hybrid bearings (FGHJ 40), hollow shafts in inch sizes

Incremental rotary encoders for heavy industry

The incremental rotary encoders FG 40 (solid shaft) / FGH (J) 40 (hollow shaft) can be deployed in a wide variety of applications to measure the speed of standard, auxiliary and secondary drives in heavy industries such as steel and rolling mills, in mining operations as well as in ports and crane systems. When attaching with an isolated coupling (solid shaft) or with optionally available isolating hybrid bearings (hollow shaft) the incremental rotary encoders protect the drivetrain against damaging shaft currents. The heavy duty incremental rotary encoders offer a high signal quality and, if required, a high pulse rate for dynamic feed-back control across the entire speed range. In particular the rugged foot construction facilitates simple attachment of further encoders at the second shaft end.

1

1 2

2 3

3 4

4| Attribute | Value |

|---|---|

| Supply voltage | 12-30 VDC (5 VDC optional) |

| Signal amplitude | HTL or TTL, Sin/Cos |

| Pulse rate | HTL/TTL: 500, 600, 1000, 1024, 1200, 1300, 2000, 2048, 2400, 2500 |

| Special pulse rates | HTL/TTL: 4000, 4096, 4800, 5000, 8192, 10000, 12000, 16000, 16384, 20000, 25000, 40000, 50000 bis 1 Million |

| Standard pulse rates Sin/Cos | 500, 600, 1000, 1024, 1200, 1300, 2500 |

| Output signals | 0°, 90°, N, status and inverted signals |

| Maximum frequency | Solid shaft: up to 6000 rpm / 200 kHz |

|

|

Hollow shaft: up to 4000 rpm / 200 kHz |

| Electrical connection | Terminal strip in a terminal box, Fixed cable, 12-pole round connector Burndy, 15-pole industrial connector, FOC connector in a terminal box |

| Construction type / Ø shafts | Solid shaft (B5, B35) / Ø 11 mm, Ø 14 mm with feather key |

| Construction type / Ø shafts | Through hollow shaft / Ø 16 mm, Ø 19 mm, Ø 20 mm with keyway; Ø 16 mm, Ø 25 mm without keyway with clamp, Blind hollow shaft in inches / Ø 3/8“, Ø 1/2“, Ø 5/8“, Ø 3/4“, Ø 7/8“, Ø 1“ with clamping ring |

| Device temperature range | 0 °C to +70 °C, -25 °C to +85 °C, -40 °C to +85 °C, -5 °C to +100 °C |

| Degree of protection | Up to IP66 / IP67 |

| Device options | Redundant incremental output |

|

|

S: Electronic overspeed switch with two mutually independent, programmable switching points. |

|

|

FOC: As an alternative to conventional signal transmissions via copper cables it is also possible to transmit encoder signals via a fiber optic cable. |

|

|

N: Mechanically fixed reference pulse (N), one square-wave pulse per revolution, with inverted signal. |

|

|

2F: Twice as many basic track pulses by combining the 0° and 90° tracks. |

|

|

B: Rapid direction of rotation sensing at each edge of 0° and 90° tracks. |

|

|

B2: Rapid direction of rotation sensing at each edge of 0° and 90° tracks; additional standstill detection. |

|

|

B3: Direction of rotation dependent output signals. This option supports counter cards with separate UP/DOWN pulse inputs. Basic track signals are issued at optional output 1 when rotation is clockwise and at optional output 2 when rotation is counterclockwise. |

|

|

SH: 1 Vpp signals sin, cos, reference pulse. Status as HTL signal; all signals each with respective inverted signals. |

|

|

ST: 1 Vpp signals sin, cos, reference pulse. Status as TTL signal; all signals each with respective inverted signals. |

| Mechanical options | Second shaft end with B14 flange for attachments (solid shaft construction type only) |

|

|

Additional foot (solid shaft construction type only) |

|

|

Isolated ball bearing (hollow shaft construction type only) |

|

|

MI: Saliferous environment |

|

|

MS: Wet areas in rolling mills |

|

|

Hollow shaft devices: Torque bracket (on request) |

| Weight | Approx. 3.5 kg |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel