Planetary gears / Angular planetary gears

PDF Download

Short info

- Small, light, space-saving

- Low-noise

- Lubricated for life, low maintenance

- High gear ratio 3:1 to 100:1

- Spiral bevel gears

- Easy to mount

Product overview right angle-bevel-planetary gearboxes

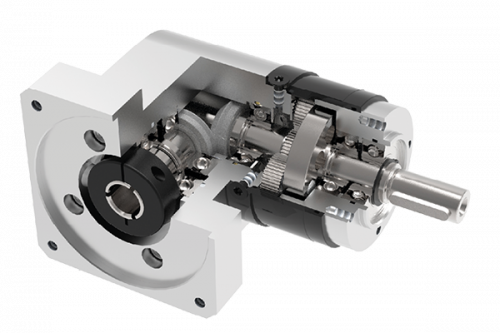

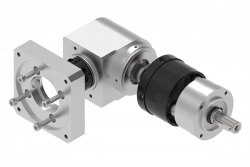

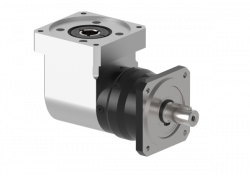

The new right angle planetary gearbox BPCE combines the features of the well known,

compact, spiral toothed and low noise ATEK bevel gears with those of a planetary gearbox.

The spiral bevel gear stage ensures quiet and compact power transmission in a right angle, the

planetary gearbox offers high torques and high gear ratios in the narrowest space. In addition, the combination impresses with strong torsional stiffness and low backlash.

The

motor flange of the right angle planetary gearbox is freely configurable and can be individually

adapted to your motor.

For maximum flexibility, the right angle planetary gears are low-maintenance, lifetime-lubricated

and optimized for mounting in all mounting positions. This gives you the best possible flexibility

for the positioning in your application. Different sizes types and ratios are available for your

application requirements.

The new economy gearbox design gives a very high price/performance ratio coupled with short delivery times.

Technical data | BPCE right angle-bevel-planetary gearboxes

| Eigenschaft | Wert |

|---|---|

| Toothing of the bevel gear | Spiral toothed |

| Toothing of the planetary gear | Straight toothed |

| Number of planetary stages | 1- or 2 |

| Ratio - bevel gearbox | 1:1 |

| Ratio - bevel gearbox | 3:1 to 100:1 |

| Output shaft bearing | Deep groove ball bearing |

| Seal | 2 RS- bearing seal |

| Lifetime (L 10h) | 20.000 h |

| Operating temperature | -25 °C / +90 °C |

| Protection class | IP 54 |

| Lubrication | Fett |

| Maintenance intervals | None, lifetime lubricated |

| Mounting position | All sides |

Product overview planetary gearbox

The planetary gearbox PCE is easy to install, lifetime-lubricated and compact. Version E combines all the advantages of our economy line.

Technical data| PCE planetary gearbox

| Eigenschaft | Wert |

|---|---|

| Toothing of the planetary gear | Straight toothed |

| Number of planetary stages | 1- or 2 |

| Ratio - planetary gearbox | 3:1 to 100:1 |

| Output shaft bearing | Deep groove ball bearing |

| Seal | 2 RS- bearing seal |

| Lifetime (L 10h) | 20.000 h |

| Operating temperature | -25 °C / +90 °C |

| Protection class | IP 54 |

| Lubrication | Grease |

| Wartungsintervalle | Keine, Lebensdauergeschmiert |

| Operationg mode | A1 |

| Mounting position | All sides |

Repair and services

The quality of our gearboxes is an important part of our philosophy. We try to design our gearboxes according to the needs of our customers in such a way that we meet both the requirements for performance and economy.

For FLOHR, however, customer service does not end with the handover of the product. Each of our gearboxes is well documented and should give you a long service life. We also offer a full repair and maintenance service for all of our gearboxes.

In order to be able to provide any type of repair and service as quickly as possible, we offer our customers a well thought-out service strategy, which also includes the storage of special parts and a rolling exchange of strategically relevant parts. In conjunction with this, we offer a repair, maintenance and service for all of our customers' transmissions, irrespective of brand. With a quick and professional damage analysis, you will immediately receive a cost estimate for the necessary repair measures. After approval, we guarantee reliable processing of the repair or service order.

Thanks to our service strategy, we have already had very good experiences with our customers. Together with you, we agree on maintenance intervals in order to prevent damage and reduce downtimes to a minimum. However, should an unscheduled problem occur, you will be immediately supported by our team.

Talk to us

about the service and maintenance concepts - we will be happy to support you

with your planning!

Downloads

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel