Friction torque limiters

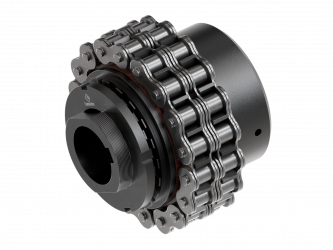

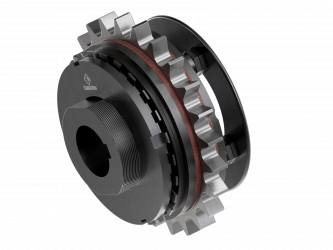

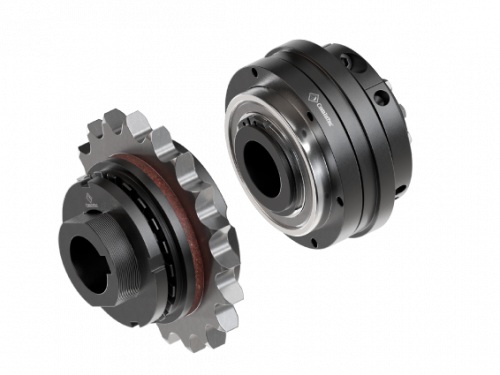

Sliding safety coupling where a plate wheel, pulley or other transmission component is interposed between two friction rings. Upon reaching

the torque sliding ensures conti nuity in the transmission without damaging the components. The minimum to have a low cost protection.

- Protects the motor-gearbox in case of accidental collision

- Protects the film of wrapping machines in case of higher tension

- Absorbs static torques without disengaging

- Protects the gear in case of short product jam

On request

- Complete with transmission gear, fully turned and mounted (plate wheel, pulley, gear pair)

- Possibility of connections with bore and keyway, locking assembly or other locking systems

- Anti-corrosive surface treatments

Downloads

-

Friction torque limiter

(2601 KB)

Friction torque limiter

(2601 KB)

Short info

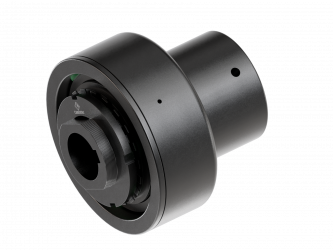

- Simple and economic friction torque limiter

- Suitable for dusty conditions without need of timing between gearbox and output

- Silent overload without vibration

- Protection in both rotation directions

- Asbestos-free friction discs

- Simple and precise torque setting by adjusting the locking ring

- Innovative calibration system for an immediate calibration of the device

Main applications

- Forming machines

- Conveyors

- Automotive

- Agricultural machines, woodworking machines

Combination variants with coupling

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel