SpiderGrip End Effektors

SpiderGrip™ is a modular, non-adjustable end effector solution engineered for high-precision, heavy-duty geometry setting applications. Spidergrip offers a standard cost effective solution by making it easy for each component to be replaced individually in the robotic cell without recertification by CMM, dramatically reducing product downtime and eliminating the need for a second, spare end-effector.

Downloads

Markets

- Aerospace

- Automotive

Appications

- Fixturing and Testing

- Welding

- Assembly

Product overview

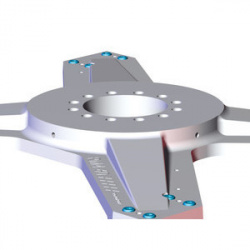

Mid Mount Assemblies

SpiderGrip’s heavy duty mid mount assemblies feature robot interface, hole patterns and accessible dowel holes. These mounts are engineered for end effectors in materials handling applications.

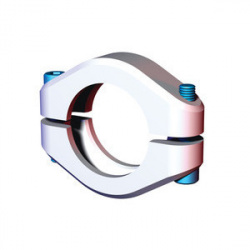

Edge Mounting Brackets

SpiderGrip’s edge mounting brackets are available in inline, offset, or 90° edge part with 15mm, 25mm, or 50mm face offset. Depending on your application, you can select from optional mounting pattern dimensions.

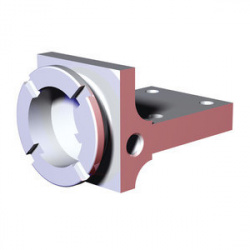

Base Anchors

SpiderGrip’s patented collar/key design and engineered breakaway base anchor provides quick crash recovery. These breakaway anchors work with a variety of mounts that are attached by dowels into the anchor’s dowel holes.

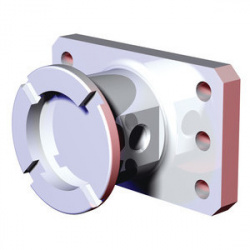

Collar Assemblies

SpiderGrip’s patented collar assemblies for end effectors are engineered to maintain an equal gap on each side of the assembly. These steel units include one collar assembly, one x-key assembly, and patch-lock fasteners.

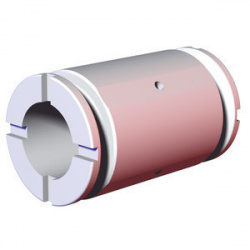

Booms

SpiderGrip’s carbon fiber reinforced booms utilize a hollow tube design that allows electrical and pneumatic lines to run internally reducing potential for failure. Booms are available in lengths of 50mm ±0.02 to 350mm ±0.02 and weights of .20 kg to 1.74 kg.

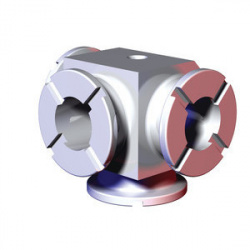

Junctions

SpiderGrip’s end effector junctions feature 2, 3, 4 and 5-way adapters (faces) for attaching SpiderGrip components to one another to construct "T, X, Y" shapes and 90 degree junctions. These junctions utilize locating holes for accurate measuring.

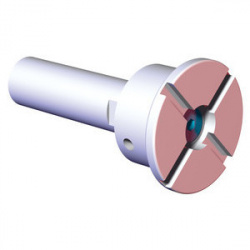

Single End Extension

SpiderGrip’s single end extensions can be used to add linear adjustment to the 360° (3) axes adjustment, when used in conjunction with transition swivel arms or transition blocks. These extensions use a convenient, one-bolt design for quick setup, easy assembly, and adjustment.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel