Servo bevel gearboxes

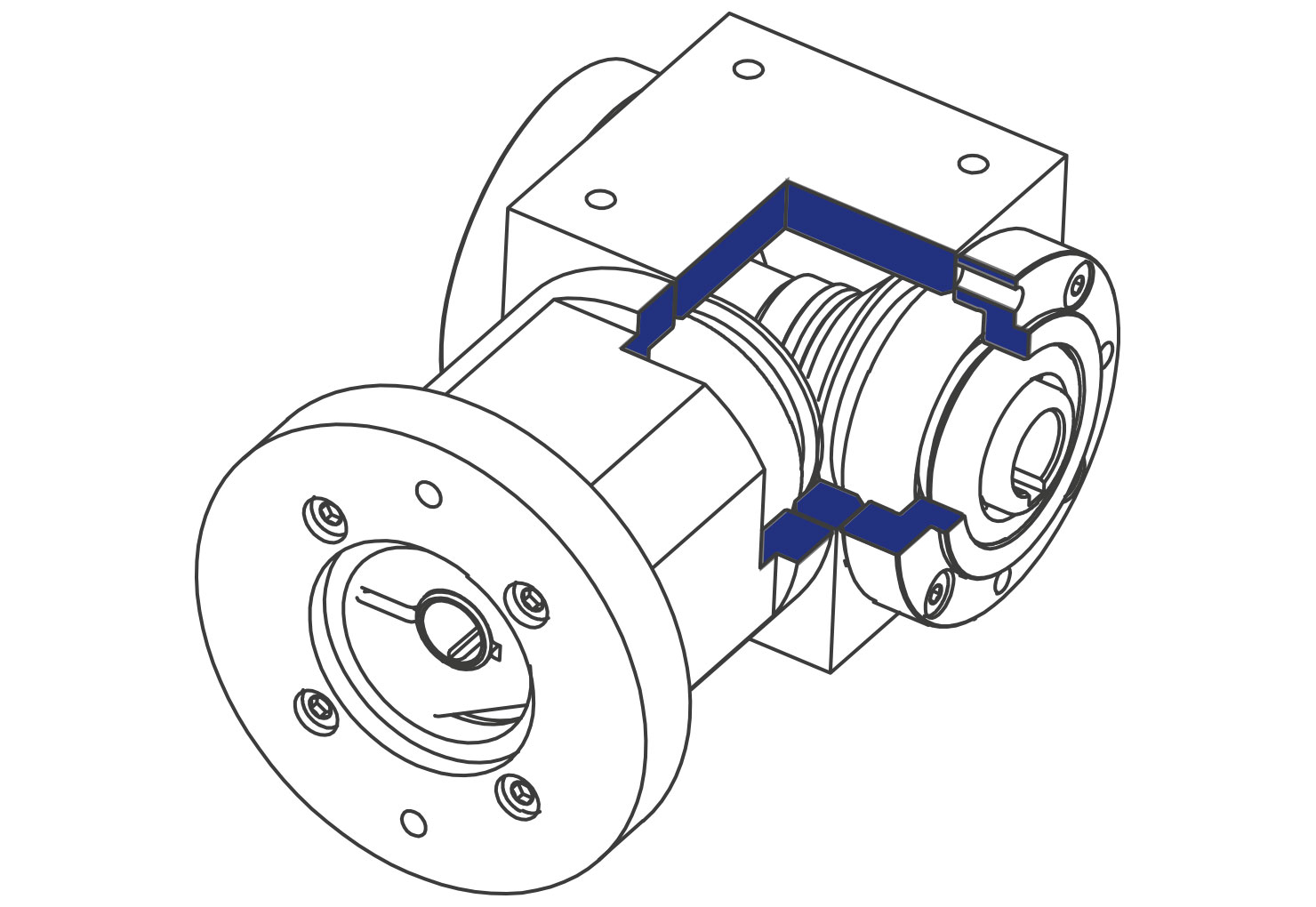

Special servo gears have been developed for the requirements of highly dynamic servo motors. The design is formed by the proven series of bevel and worm gears.

The combination of a large number of motor flanges and a plug-in, backlash-free clamp coupling enables an adaptation to most servo motors. The modular system also makes it very easy to subsequently change the motor flange and the motor-side coupling half.

Servo gears (precision gears) are high-precision and highly dynamic servo

drive solutions. These high-performance gears are up to todays high demands in

every respect. It is not without reason that they are used worldwide in the

automotive industry, among other things.

PDF Download

-

Servo gearboxes (precision gearboxes)

(5652 KB)

Servo gearboxes (precision gearboxes)

(5652 KB)

-

Servogetriebe VCE

(6227 KB)

Servogetriebe VCE

(6227 KB)

Short info

- High speed up to n1 = 8000 rpm

- Minimized backlash (optional)

- High precision

- Cast iron body

Markets

- Automation

- Positioning drives

- Robotics

- Highly dynamic applications

- Automotive

Whether application-specific drive solutions for the construction of

special machines or series products for general machine construction, the

modular system offers a wide range of drive solutions of the highest product

and process quality at a competitive price/performance ratio.

Product overview

Type LC - Servo bevel gearboxes

- Gear ratios: i =

1:1 to 4:1

- Maximum output

torque: 16 Nm

- 2 gearbox sizes

with lengths of 35 to 45 mm

- Suitable for fi

tting IEC standard motors

- Low-backlash

construction < 10 angular minutes possible

- Housing made of

aluminium

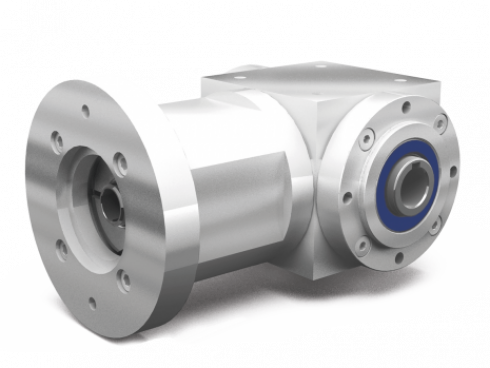

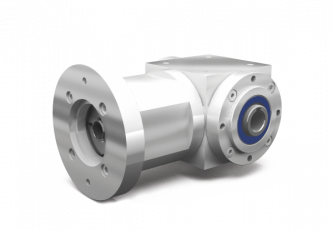

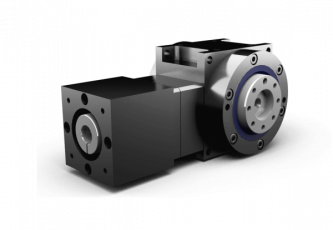

Type VC - Servo bevel gearboxes

- Gear ratios: i = 1:1 to 6:1

- Maximum acceleration torque on output: 700 Nm

- 6 gearbox sizes with lengths of 65 to 200 mm

- Minimised circumferential backlash (optional)

- Housing made of grey cast iron

- Bevel gearboxes suitable for fitting servo-motors

- Non-positive connection between motor and gearbox

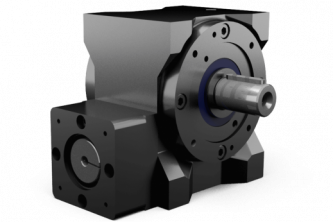

Type HC - Servo hypoid gearboxes

- Gear ratios: i =

3:1 to 15:1

- Maximum acceleration torque on output: 2160 Nm

- 6 gearbox sizes;

centre-to-centre distance: 90 to 260 mm

- Minimised

circumferential backlash (optional)

- Housing made of

aluminium

- Hypoid gearboxes

suitable for fitting servo-motors

- Non-positive

connection between motor and gearbox

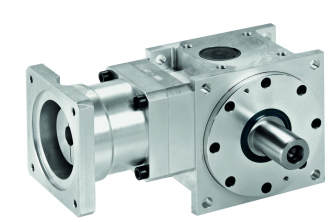

Type SC – Servo worm gearboxes

- Gear ratios: i =

10:1 to 20:1 (i > 26 upon request)

- Maximum

acceleration torque on output: 1100 Nm

- 5 gearbox sizes;

centre-to-centre distance: 40 to 100 mm

- Minimised

circumferential backlash (optional)

- Housing made of

grey cast iron

- Worm gearboxes

suitable for fitting servo-motors

- Non-positive

connection between motor and gearbox

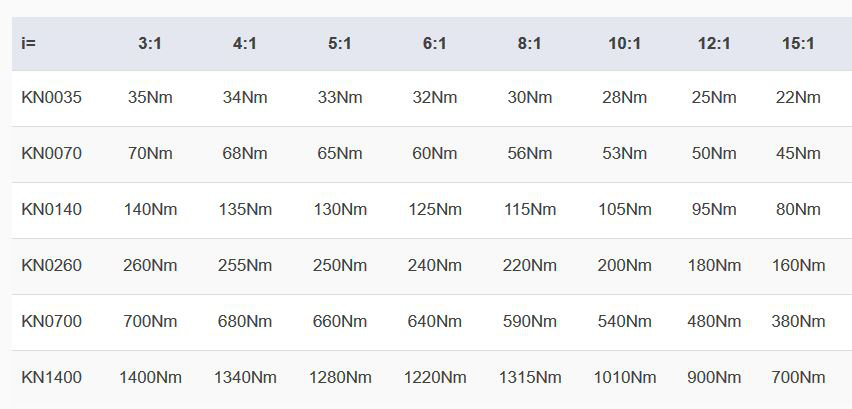

Servoline - bevel gearboxes

- Gear ratios: 3:1 to 15:1

- 6 gearbox sizes

- Torque up to 1400 Nm

- Speed up to 8000 rpm

- Hypoid spiral gearing (Klingelnberg)

- Low torsional backlash

- High power

- High gearbox rigidity

- High specification quality bearings

- Wide range of motor flange combinations

- Maintenance-free

lifetime lubrication

Technical data

Type LC

| Characteristic | Standard |

|---|---|

| Teeth | Bevel gear set, spiral-toothed |

| Housing / Flanges | Aluminium |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges. |

| Shaft | Drive shaft with clamping hub; fit ISO 6 tolerance with parallel keyway: acccording to DIN 6885 |

| Hollow shaft | Fit with ISO H7 tolerance with parallel keyway: according to DIN 6885 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | -10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | – |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required |

| Lubricants | Synthetic lubricants |

The

dimensions of the gearboxes are identical with those of the L-type gearboxes

The motor-specific adapter flanges are under development. Please enquire

gearboxes for your case of application.

Type VC

| Characteristic | Standard |

|---|---|

| Teeth | Spiral-toothed, hardened bevel gears |

| Gear ratio | 1:1 to 3:1 (to VC065), to 6:1 (from VC090) |

| Housing / Flanges | Grey cast iron / aluminium |

| Threaded mounting hole | On all housing surfaces without flange and on all flanges. |

| Shaft | Material 1 C45, shaft end fit ISO 6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shaft end fit ISO 7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | -10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 20 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the fi rst 500 service hours and then every 5000 service hours. |

| Lubricants | Synthetic lubricants |

| Motor flange | Aluminium |

| Coupling | Insertable, flexible claw coupling, suitable for servo-motors |

|

|

For smooth motor shafts clamping hub KN |

|

|

For smooth motor shafts tension ring hub SN |

|

|

For motor shafts with parallel key clamping hub with groove KN |

Type HC

| Characteristic | Standard |

|---|---|

| Teeth | Spiral-toothed, hardened bevel gears |

| Gear ratio | 8:1 to 15:1 |

| Housing / Flanges | Aluminium / steel |

| Threaded mounting hole | On the sides 1 and 2 and on the drive flange |

| Shaft | Material 1 C 45, shaft end fit ISO 6 tolerance |

| Hollow shaft | Material 1 C45, shaft end fit ISO 6 tolerance |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | -10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 5 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 30.000h in S5 operation |

| Oil change intervals | Not required if the oil temperature is kept < 90°C. The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the first 500 service hours and then every 5000 service hours. |

| Motor flange | Aluminium |

| Lubricants | Synthetic lubricants |

| Coupling | Insertable, flexible claw coupling, suitable for servo-motors |

|

|

For motor shafts without parallel key Bellows coupling BK |

|

|

For motor shafts with parallel key Bellows coupling BKN |

Type SC

| Characteristic | Standard |

|---|---|

| Teeth | Hardened and ground worm shaft / bronze worm gear |

| Gear ratio | 10:1 to 20:1 |

| Housing / Flanges | Grey cast iron / aluminium |

| Threaded mounting hole | On gearbox side 1 and on the flanges |

| Shaft | Material 1 C45, shaft end fit ISO j6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shaft end fit ISO H7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 5 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000 h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the fi rst 500 service hours and then every 5000 service hours. |

| Motor flange | Aluminium |

| Lubricants | Synthetische Schmierstoffe |

| Coupling | Insertable, flexible claw coupling, suitable for servo-motors |

|

|

For smooth motor shafts clamping hub KN |

|

|

For smooth motor shafts tension ring hub SN |

|

|

For motor shafts with parallel key clamping hub with groove KNN |

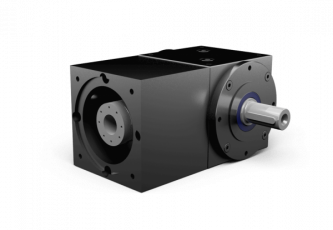

Type VCE

| Characteristic | Standard |

|---|---|

| Teeth | Planetary gears: straight-toothed spur gears / Bevel gearboxes: spiral-toothed bevel gears |

| Gear ratio | 3:1 to 15:1 |

| Housing / Flanges | Planetary gears: aluminium, steel/ bevel gearboxes: Grey cast iron, steel |

| Threaded mounting hole |

|

| Shaft |

|

| Hollow shaft |

|

| Radial shaft seal ring |

|

| Ambient temperature | –10°C to +90°C. The values of the performance tables are valid for +20°C |

| Circumferential backlash | < 6 / 15 / 18 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | > 15.000 h |

| Oil change intervals |

|

| Motor flange |

|

| Lubricants | Planetary gear: grease / bevel gear: oil |

Servoline

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel