Duplex worm gearboxes

The Duplex worm gearbox is a high-precision servo gearbox for applications requiring low backlash. This gearbox offers very low backlash and very high torsional stiffness.

If required, the Expert version can be readjusted at any time within the gearbox's service life, thus reducing the backlash on the output shaft.

We supply high-quality worm gearboxes with outstanding properties for your requirements:

Downloads

-

Duplex worm gearbox standard

(7286 KB)

Duplex worm gearbox standard

(7286 KB)

Application examples

- Machine tools

- Rotary tables

- Milling drives

- Industrial robots

- Pick-and-place systems

- Semiconductor manufacturing

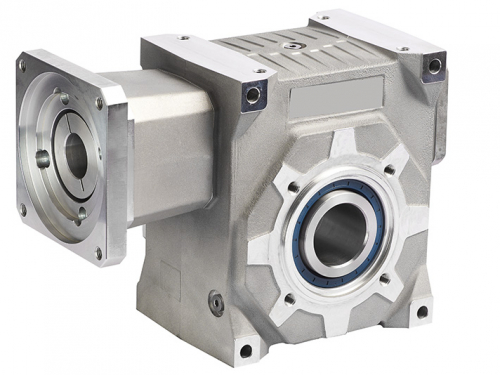

Low backlash worm gearbox standard

Shortinfo

- Precision levels: Expert, Medium and Basic

- Oversized taper roller bearings

- Special bronze alloy

- Eight sizes: 25 to 110

- Torsional backlash: < 1 arcmin. (0,016°)

- Input speeds up to 6,000 rpm

- Efficiency up to 98 %

- Ideal for high precision requirements

- Low mass moments of inertia

- High torsional rigidity

- Maintenance-free

- Lubricated for life

- Any mounting position

- Simple motor mounting with clamping via servo coupling

Versions

- Hollow shaft

- Robot flange

- Hollow output shaft with keyway

- Hollow output shaft with hub

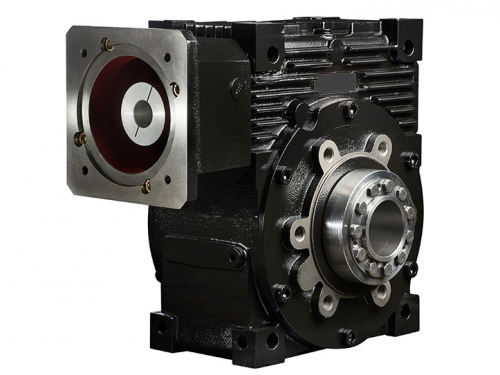

Low backlash worm gearbox heavy duty

Shortinfo

- Precision levels: Expert and Medium

- Oversized taper roller bearings

- Special bronze alloy

- Three sizes: 125 to 200

- Input speeds up to 6,000 rpm

- Efficiency up to 96 %

- Low mass moments of inertia

- High torsional stiffness

- Maintenance-free

- Lubricated for life

- Any mounting position

- Simple motor assembly

Versions

- Hollow shaft

- Single output shaft

The Duplex-System

The technical design of the DUPLEX wormgear sets is based on the fact that both the worm shaft and the worm wheel have different modules (profiles) for the left and right flank. With this technology, the worm profile becomes stronger from pitch to pitch, so that there is a reduction in play through axial displacement of the worm.

The axial displacement of the worm shaft is carried out either by a special adjustment adapter available from the catalogue or by appropriate adjustment devices supplied by the customer.

Downloads

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel