Standard worm gearboxes

Due to its mode of operation, a worm gears with large gear ratios allow a very high reduction in speed. With worm gears, the two shafts cross at a defined distance (A). This center distance is reflected in the gearbox specification. (Example: S 100 – centre distance 100 mm)

Worm gears are high-precision and rugged offset gears. These

high-performance gears meet the high demands every time and in every respect.

They are quiet and not so sensitive to impacts. It is not without reason that

they are used in conveyor systems worldwide, amongst other things.

Downloads

-

Worm gearboxes

(4050 KB)

Worm gearboxes

(4050 KB)

Short info

- Robust, powerful, low-noise

- Grey cast iron housing

- Axle offset between input and output

- Maintenance-free

Markets

- Stage and theatre technology

- Separating machines

- Conveyor systems

- Profile processing machines

- Extrusion machines

Whether application-specific drive solutions for the construction of special machines or series products for general mechanical engineering: the modular system offers a wide range of drive solutions of the highest product and process quality at a competitive price/performance ratio.

Product overview

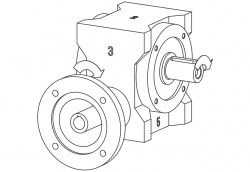

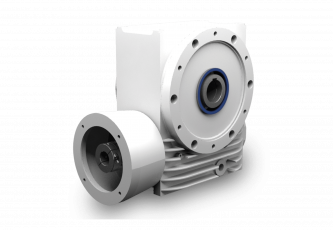

Type S - Standard worm gearboxes

- Nominal gear ratios: i = 10:1 to 83:1

- Maximum output torque: 1765 Nm

- 8 sizes, centre-to-centre distance of 040 bis 100 mm

- Housing made of grey cast iron

- Low-backlash construction S1 < 6 angular minutes

S2 < 10 angular minutes

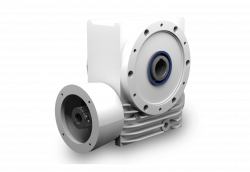

Type SL - Type S with flange for motor mounting

- Nominal gear ratios: i = 10:1 to 83:1

- Maximum output torque: 1765 Nm

- 5 sizes, centre-to-centre distance of 040 to 100 mm

- Housing made of grey cast iron

- Low-backlash

construction

- Suitable for fitting IEC standard motors

- Drive side with hollow-bored shaft and flange

S2 < 10 angular minutes

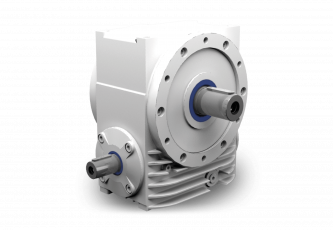

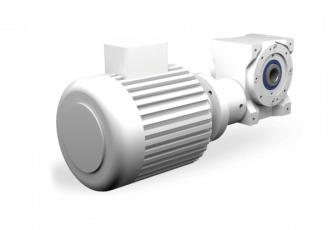

Type SLM - Type SL with motor (gearbox motor)

- Nominal gear ratios: i = 10:1 to 83:1

- Maximum output torque: 1765 Nm

- 5 sizes, centre-to-centre distance of 40 to 100 mm

- Low-backlash

construction

- With mounted IEC standard motor

- Positive couplingde of grey cast iron

S2 < 10 angular minutes

Technical data

Types S 040 | S 050 | S 063 | S 080 | S 100

| Characteristics | Standard |

|---|---|

| Toothing | Hardened and ground worm shaft / bronze worm gear |

| Gear ratio | 10:1 to 83:1 |

| Housing / Flanges | Grey cast iron |

| Threaded mounting hole | On gearbox side 1 and on the flanges |

| Shaft | Material 1 C45, shaft ends greased Fit with ISO j6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shafts greased Fit with ISO H7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for 20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the first 500 service hours and then every 5000 service hours. |

| Lubricant | Synthetic lubricants |

Types SL 040 | SL 050 | SL 063 | SL 080 | SL 100

| Characteristics | Standard |

|---|---|

| Toothing | Hardened and ground worm shaft / bronze worm gear |

| Gear ratio | 10:1 to 83:1 |

| Housing / Flanges | Grey cast iron |

| Threaded mounting hole | On gearbox side 1 and on the flanges |

| Shaft | Material 1 C45, shaft ends greased Fit with ISO j6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shafts greased Fit with ISO H7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for 20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000h |

| Oil change intervals | Not required if the oil temperature is kept below 90°C. The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the first 500 service hours and then every 5000 service hours. |

| Lubricant | Synthetic lubricants |

| Flange | Suited for the mounting of IEC motors, models IM B5 and B14 |

| Coupling | Three-piece claw coupling |

Types SLM 040 | SLM 050 | SLM 063 | SLM 080 | SLM 100

| Characteristics | Standard |

|---|---|

| Toothing | Hardened and ground worm shaft / bronze worm gear |

| Gear ratio | 10:1 to 83:1 |

| Housing / Flanges | Grey cast iron |

| Threaded mounting hole | On gearbox side 1 and on the fl anges |

| Shaft | Material 1 C45, shaft ends greased Fit with ISO j6 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Hollow shaft | Material 1 C45, shafts greased Fit with ISO H7 tolerance with parallel keyway: according to DIN 6885 Sheet 1 |

| Radial shaft seal ring | NBR, form A |

| Ambient temperature | - 10°C to +90°C. The values of the performance tables are valid for 20°C |

| Circumferential backlash | < 30 arcmin |

| Protection class | IP 54 |

| Corrosion protection | Prime coat; layer thickness > 40 µm |

| Bearing life L10h | More than 15.000h |

| Oil change intervals | Not required if the oil temperature is kept < 90°C The lifetime of the bearings can be increased by the factor 1.5 if the oil is changed after the first 500 service hours and then every 5000 service hours. |

| Lubricant | Synthetic lubricants |

| Motor | IEC standard motor in the prescribed efficiency class. |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel