MAG Ex Incremental und MAGA Ex Absolute

Extremely rugged and explosion-proof

Our bearingless magnetic encoders MAG incremental have been proving their qualities for a long time in applications exposed to extreme environmental conditions. Thanks to their compact construction they are particularly able to demonstrate their strengths when deployed in confined spaces. Ex certification is a new development for the MAG Ex incremental model. Consequently, we are able to increase the spectrum of applications for these extremely rugged, contactless functioning encoder systems. The MAG Ex is certified for harsh environments subject to explosion hazards. Examples of the new fields of applications for the encoders include oil and gas production, offshore platforms, pipeline compressor stations and petrochemical installations.

Tailor-made solutions

With a wide variety of additional options MAG/MAGA Ex facilitate tailor-made encoder integration solutions. For example, these include a second scanning head to enable transmission of redundant signals. And it is possible to fit both magnetic encoders with an external transmitter/decoder to provide additional FOC signal transmissions up to 1000 meters.

MAG Ex incremental and MAGA Ex absolute

The explosion-proof encoder systems MAG Ex incremental with HTL or TTL output signals are available with immediate effect. Ex certification for the encoder systems MAGA absolute with SSI output signals is in preparation. Both the MAG Ex incremental and the MAGA Ex absolute will receive ATEX certification for Zone 2.

Long lasting and flexible

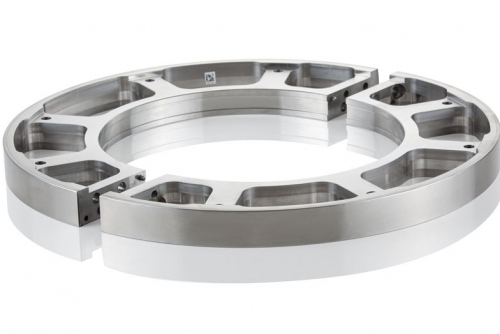

Both versions of our Ex certified magnetic encoder systems are extremely rugged and designed for a long service life. They are nonwearing thanks to their bearingless design and contactless scanning functionality. A special stainless-steel protection cover additionally shields the encoders from the effects of the environment. The scanning head is seawater-proof by design (IP68) and, as a consequence, is also suitable for offshore applications. Furthermore, because they can be directly attached to shafts with or without a free shaft end our MAG Ex incremental and MAGA Ex absolute encoders offer maximum engineering freedom. The split pulse wheel option is a practical alternative for retrofitting and upgrade projects.

Technical data MAG EX / MAGA Ex

| Attribute | Value |

|---|---|

| ATEX marking | II 3G Ex nC IIC T4 Gc |

| Supply voltage | 12-27 VDC |

| Temperature range | -30 °C...+85 °C |

| Vibration resistance | Up to 20 g |

| Shock resistance | Up to 200 g |

| Degree of protection | IP68 / IP66/ IP67 |

| Max. speed | Up to 4000 rpm (depending on diameter of pulse wheel) |

| Hollow shaft diameter | 50-380 mm |

| Pulse wheel design | Optional one-piece or split |

| Pulse wheel attachment | Optional with screw connection or clamping element |

| Pulse wheel protection cover | Stainless-steel protection cover welded on both sides. Protects magnetic coding against environmental conditions and electrostatic charging. |

| Axial tolerance | ± 3 mm (offset pulse wheel / scanning head) |

| Radial tolerance | 1.0 ± 0.2 mm (air gap pulse wheel / scanning head) |

| Cable connection | Fixed copper cable connection, potted. Optional cable exit left or right. |

| Cable length | Individual to meet customer requirements. Maximum cable length: 100 m. Additional FOC signal transmissions up to 1000 m possible (transmitter in separate protective Ex housing). |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - 79761 Waldshut-Tiengen (Allemagne) - Téléphone : +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.

Table des matiéres Contact Conditions générales de vente Mentions légales

Politique de confidentialité Politique de confidentialité courriel