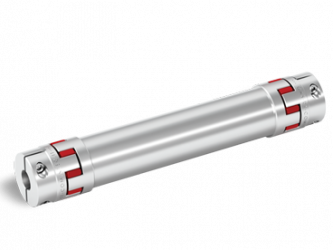

Jaw coupling / elastomeric coupling

The flexible, compact plug-in couplings GAS and GAS/SG consist of two steel hubs in accordance with EN10083/2018 with low surface roughness and a precise elastomer element that is mounted as a plug-in part. The elastomer element and the profile of the hub claws function solely through surface pressure and not through shearing. The coupling therefore remains highly reliable even with alternating torques and load fluctuations.

The presence of the elastomer assures:

- the possibility to absorb collisions and vibrations

- to compensate for unavoidable misalignments between the shafts

- silence during transmission

Description of the elastomeric element

The fundamental item of this coupling is the elastomeric element or elastomer, made in polyurethane and available in several hardness grades, for diff erent uses and applications.

The elastomer is manufactured to resist ageing, scoring, fatigue, hydrolysis and UV radiations, promoting longer life operation. It also resists main chemical agents, like ozone, oils, grease and hydrocarbons.

The elastomeric element becomes prestressed during the assembly between the relevant hub's teeth, in order to be able to transmit the motion without backlash, so torsionally rigid inside the prestressing load.

The prestressed elastomer's surface is sufficiently wide to induce a low contact pressure on the tooth of the same elastomer, reducing permanent deformations and promoting a long life.

Downloads

-

Jaw coupling

(1932 KB)

Jaw coupling

(1932 KB)

-

ELKURI Kupplung

(127 KB)

ELKURI Kupplung

(127 KB)

-

Elastische Klauenkupplung

(868 KB)

Elastische Klauenkupplung

(868 KB)

Shortinfo

- Made in steel fully turned with standard phosphating treatment

- Several elastomer hardnesses available

- High torsional rigidity

- Electric insulation between the parts

- Statically balanced

- Version with integrated locking assemblies

- Up to 55 KNm and 200 mm bore diameters

On request

- Conformity to ATEX directive possible

- Specific treatments or version fully in stainless steel

- Manufacturing made to length and customizations for specific needs

- Connection to the Torque limiter’s (safety coupling) range possible

Areas of application

Areas of application are wherever high power has to be transmitted in the drive train and start-up peaks are to be reduced by the elastomer packages. Applications are found in the entire field of mechanical engineering. Both on the motor side as a high-speed coupling for pumps, fans or compressors, for example, and at high torques for connecting gears and machines in crushing technology, mills or mixers.

Versions

Backlash free jaw coupling in steel

- Made in steel fully turned with standard phosphating treatment

- Several elastomer hardnesses available

- High torsional ridigity

- Electric insulation between the parts

- Statically balanced

- Version with integrated locking assemblies

Standard jaw coupling in steel

- Made in steel fully turned with standard phosphating treatment

- Several elastomer hardnesses available

- High compensation of misalignments

- Vibration dampening

- Statically balanced

- Modularity of the components, with different assembly versions

Backlash free and standard jaw coupling in alluminium

- Made in aluminum fully turned

- Elastomer available in different hardness

- Weight and inertia reduced

- Electrical insulation between the parties

- Statically balanced

- Modular components with different locking systems on the hubs

Backlash free jaw spacer coupling in alluminium

- Made of aluminum fully turned

- Elastomer available in different hardness

- Simple mounting thanks to the two piece clamp hub (type C)

- Radial assembly without removing the parts

- Electrical insulation between the parts

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de