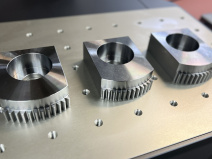

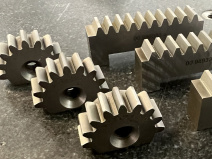

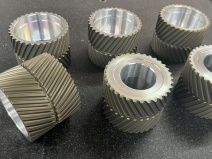

Special gears and herringbone gears

For special applications, an alternative gear geometry can be produced using the free-form milling process. The pitch accuracy is absolutely sufficient for most applications. A big advantage is certainly the surface quality and the geometry of the tooth flank, which can be freely designed.

Free-form production is used for

herringbone gears (including double helical gears) and for other more complex

tooth geometries. We would be happy to advise you on the best possible design.

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12Advantage of herringbone gearing

The

axial force component of the double helical gearing can be virtually eliminated

by the symmetrical arrangement of the mirrored helical gearing. Due to the use

of herringbone gearing, which is complex to manufacture, a left-hand and a

right-hand part are combined on one gear.

- Possibility to virtually eliminate the axial forces

- Less bearing stress from axial forces

- Particularly suitable for large gears

Please contact us for

further questions.

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de