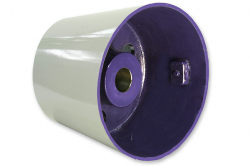

Flat belt pulleys

With over 100 years of experience in the design and manufacture of belt drives, we are a powerful partner for your drive solutions. We manufacture individual flat belt pulleys in all common profiles up to a diameter of 2,500 mm.

Flat belt pulleys are important and versatile drive

element in many areas. Flat belt drives have clear advantages, especially in

cases where the drives that are subject to shock loads, and which are also

subject to vibration. The discs are very economical and highly reliable.

In order to meet the performance requirements of our

customers, all of our drives are individually designed. Weight, moment of

inertia, geometry and performance parameters are perfectly matched to the

requirements. Due to our flexible semi-automatic molding process, there are no

model costs for the initial production. Similarly, there are no costs for any geometry

adjustments before the moulding process. This flexible process enables the most

economical production and guarantees minimum delivery times with maximum

responsiveness.

Downloads

Flat belt pulleys are usually designed with a cylindrical bore. In the case of higher power transmissions, it is also possible to work with clamping sets thanks to a reinforced hub design. Alternatively, all flat pulleys can also be manufactured as a TaperLock version (TL).

The drives

can be manufactured quickly and extremely flexibly even in the event of

changes. The batch size of 1 piece for urgent spare parts or prototypes as well

as series are not a problem.

Flat belt

pulleys for TL clamping bushes

Flat belt

pulleys with cyl. drilling

Tapered flat

belt pulleys

Band saw rolls

At a glance

Features

- Special production according to customers individual specifications or drawings

- Standard for peripheral speeds up to 42 m/s

- Maximum pulley diameter 2,500 mm

- Maximum crown width 750 mm

- Maximum pulley weight approx. 6,000

kg

Flexible moulding process | Fast delivery

- Individual model setups are not required – there are no model costs!

- Manufactured according to DIN 111

- Change requests or adaptations can be accommodated without costs

- Short term production and delivery possible

- TL standard washers in all common

diameters incl. TaperLock version of bushings 1008-5050 in stock

Materials

- Standard: Cast iron with lamellar graphite EN-GJL-200 to EN-GJL-300 (GG-20 to GG-30), DIN EN 1561

- Alternative:

Nodular

cast iron (EN-GJS-400 to EN-GJS-600) or cast steel (GS), steel welded version

or aluminum

Shaft-hub connection

- Cylindrical

bore, with and without keyway

With groove and / or set screw - Prepared for couplings, flanges,

clamping sets or TaperLock bushing

Possible designs

- Arm, plate or solid disc

- Double arm / double plate disc with stiffening ribs

- Two-piece drive pulley

- Crown crowned according to DIN 111, cylindrical or with rims

- Conical geometries or saw band rollers

- Steel / welded constructions

Balancing standards

- Standard according to DIN 21940-11 in quality grade G16

- Available in quality grades G6.3 or G2.5 on request

Surface treatment

- Primed / black oxide finish as standard

- Individual surface treatment and special painting is also possible

- Friction

coatings made of rubber, silicone and polyurethane

Why FLOHR?

- Flexible moulding process without individual models and without model cost

- Special designs according to individual customer specifications or drawings

- Pulley geometry optimally adapted to the respective drive situation

- Individual design, control, recalculation and optimization of your drive

- Individual machining (drilling, grooving, surface treatment...) according to customer specifications

- Documentation of residual imbalances and surface treatments

- Detailed documentation to prove material properties, balancing grades and surface treatments possible

- Full transparency through creation of released drawings

- Ideal for prototypes, as well as individual or series parts

- Short-term availability of urgent spare parts during machine downtime

- Extensive stock

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de