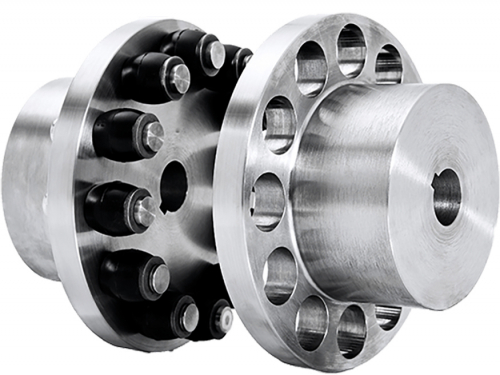

VEBOFLEX Coupling

VEBOFLEX couplings are used as compensating couplings where absolutely reliable torque transmission is required. The flexible couplings cover a wide range of requirements with their designs. With a total of 26 sizes available for couplings with torques from 200 to 1,300,000 Nm. This covers the most common sizes and forms our standard.

In addition, we are able to produce special sizes for your individual requirements. We have already manufactured numerous special sizes for the cement industry, for the mining industry and other applications in heavy industry. We cast the coupling halves without model costs and supply the coupling with the required elastomeric elements. Couplings with a unit weight of more than 3,000 kg and a diameter of 1,700 mm have already been manufactured.

The coupling halves of type WN are made of gray cast iron. The WS version made of steel enables you to use the the coupling at high speeds.

All coupling hubs with a finish bore

correspond to a minimum balancing quality of G16 (according to DIN ISO 1940 for

n = 1500 min-1 or vmax = 30 m/s, with balancing in one plane). Balancing is

based on the half-wedge principle (DIN-ISO 8821).

Downloads

-

VEBOFLEX - Elastische Bolzenkupplungen

(3452 KB)

VEBOFLEX - Elastische Bolzenkupplungen

(3452 KB)

Advantages

- Torsional elastic and vibration-damping

- Low maintenance

- Easy to assemble

- Puncture proof

- Angular, radial and axial flexible

- Direction of rotation

independent

Special sizes

We

design your individually adapted coupling for you and manufacture it in-house.

Including mechanical processing and balancing. Unit weights of up to 5 t and

maximum diameter of Ø 2,000 mm are possible.

VEBOFLEX

pin couplings dampen torque shocks and offer the possibility of increasing

critical speeds. VEBOFLEX bolt couplings are puncture-proof up to the breaking

moment of the metal parts, which is a multiple of the permissible impact

moment, and thus offer the greatest possible operational safety. VEBOFLEX pin

couplings can be used for both directions of rotation and are also suitable for

reverse operation. With the correct design of the coupling and correct

alignment during assembly, the buffers can be expected to have a long service

life.

Overriding features

- Compensation of radial,

axial and angular shaft misalignments

- Shaft misalignments

- Simple assembly as plug-in coupling

- Vibration damping

- Maintenance-free with high wear resistance

- Impact resistant

- Standard sizes quickly available from stock

- Torques >1,000 kNm possible

- Temperature resistant between -20°C to +80°C

- Materials:

CAST IRON EN-GJL-250 (GG-25) DIN 1691

STEEL S 355 J2G3 (ST 52.3) DIN 17100

Areas of application

VEBOFLEX bolt couplings have proven themselves

over decades in all areas of machine building, especially in heavy drives, as

an absolutely reliable and practically maintenance-free machine element. The

positive torque transmission is achieved by means of elastic elements subjected

exclusively to compressive stress, which deform elastically in compression The

progressive spring characteristics and the very good damping properties of the

buffer effectively counteract the dangerous build-up of torsional vibrations

that occur.

Functions

The

positive torque transmission is effected by elastic elements subjected

exclusively to compressive stress, which deforms elastically in compression.

The progressive spring characteristics and the very good damping properties of

the buffers effectively counteract the dangerous buildup of torsional

vibrations.

The

optimized round-ball buffer shape assists the compensating function in the

event of existing angular or radial misalignments, and restoring forces are

minimized.

The

ground bolts are fixed backlash-free by means of

a conical seat. This effectively prevents possible deflection of the locating

bore and the formation of fretting corrosion.

The

crowned buffers can be mounted in a plug-in manner.

The bolts and buffers can be replaced without axial displacement of the motor

or the machines. Decoupled machines can be removed radially. The buffers can be

used at ambient temperatures from -30°C to +80°C. They are electrically

conductive and resistant to oil and many other media.

Balance quality according to DIN 21940

All coupling

hubs have finish bores and correspond to a minimum balancing quality G16

(according to DIN ISO 21940 for n = 1500 min -1 or vmax. = 30 m/s, with

balancing in one plane). Balancing is performed according to the shaft and

fitment key convention (DIN-ISO 8821). If finer balancing is required for the

operating or system behavior, this must be agreed separately. For

circumferential speeds v > 30 m/s, we recommend balancing to quality grade G

6.3, which can also be carried out in two planes if necessary.

Design and calculation

We will be happy to

support you in the selection of the coupling. Information on assembly,

disassembly as well as technical data can also be found in our catalog for

download. VEBOFLEX drawbar couplings can also be adapted to specific

requirement profiles in many cases. A large number of already completed

applications are available. Our project department will be pleased to advise

you.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de