Partners

Together with our partners we become a powerful system provider in drive technology

Mechanical engineering is changing. The increasing transparency in purchasing as well as the ongoing internationalization of the markets force top performance and bring both opportunities and risks for companies in the drive technology sector.

At FLOHR, the strategy from early on was to further strengthen core competencies and to create indispensable added value for our customers through optimal connections with high-performance partners. Our goal is to offer the competence and specialist knowledge of the entire drive train through tailor-made support and thus generate maximum added value as a system provider for our customers.

We are proud of the long-standing

relationships with our key partners. Some connections have existed here for

more than 40 years. Together, step by step, cooperation was established and

sustainably strengthened. In retrospect, we would not have been able to survive

so successfully on the market without the optimal combination of our own

products as well as the components of

our core partners.

Our Partners

With its foundry, Lütgert & Co. GmbH has specialized in

the manufacture of drive components made of gray cast iron and can draw on many

decades of “Made in Germany” manufacturing experience since it was founded in

1913. With the associated mechanical processing

the high-quality drive technology has been manufactured ever since and

delivered to customers throughout Germany and internationally according to

individual specifications.

In the classic hand molding shop for individual

parts and small series, Lütgert manufactures unit weights of up to 6,000 kg.

The rotationally symmetrical parts are usually manufactured without model

costs. From the design and optimization of the drives to precise and complete

production according to customer specifications, the company offers complete

added value at the highest level. In addition to processing its own products,

Lütgert also undertakes demanding sub-contract work for its customers.

The MAT Malmedie Antriebstechnik GmbH is one of the world's leading manufacturers of mechanical couplings and develops, designs, manufactures and sells gear couplings, barrel couplings and safety couplings for the steel industry, crane and mining and heavy machinery construction.

Originally

founded in 1873 as a machine factory, the company has developed through

innovation, knowledge and experience into a specialist in power transmission.

As early as 1958, MALMEDIE invented the so-called barrel coupling which is now

a worldwide standard for the connection between gears and cable drums, which is

required for crane hoists, for example. The product range now includes many

mechanical components for drive technology, above all couplings of various

types, for steel works and for harbours technology. Numerous patents

demonstrate the company's great innovative strength.

Destaco, a Dover Corporation company, is a global leader in the design and manufacture of high-performance automation, workholding and remote handling solutions. The company offers a comprehensive portfolio of products for precise motion, placement and control solutions that enable manufacturers worldwide to optimize their productivity.

Ever since

1915, DESTACO has grown through continuous product development and has acquired

strong product brands to offer a comprehensive product portfolio. The product

range includes grippers, swivel units and linear units, rotary tables and cycle

conveyor belts, manual and pneumatic clamping solutions, power clamps and

swivel units, end effector solutions and solutions for the areas of remote

handling and containment. All products can be adapted to individual customer

requirements and tailor-made solutions can be developed.

As a medium-sized gear manufacturer, ATEK Antriebstechnik Willi Glapiak GmbH can look back on more than 75 years of tradition. For more than 30 years, everything has “revolved” around right-angled power transmission. Whether as a power drive in a conveyor system or as a control drive in highly dynamic machine tools - ATEK offers a tailor-made solution for almost every application in which torque is transmitted at right angles.

The

performance of the ATEK is very high, especially in the series area and with

flexible adjustments in the field of servo technology and automation. The fast

delivery time is another advantage of our partnership with ATEK, which has

existed since 2013. FLOHR is the agency for ATEK in

Switzerland and Austria and is convinced of the synergies that result from

powerful partners in drive technology.

The Johannes Hübner Fabrik elektrischer Maschinen GmbH stands for new standards in rotary encoders and power sensors for drive technology. The expansion of the product areas represents an important and ideal addition to our established program in drive technology. Especially in areas of heavy industry, such as the steel industry, there are excellent synergies, which mean significant added value for our customers.

Johannes

Hübner Giessen develops world-leading products and system solutions for extreme

operating conditions. The intelligent and programmable encoders support

predictive maintenance and make an important contribution to automation and

Industry 4.0. They ensure high system availability and set new standards in the

area of functional safety in heavy industry.

The ZZ-DriveTech GmbH,emerged from the Zuffenhausen gear factory and ZZ-antriebe GmbH, and is based on more than 100 years of experience of progress and innovation in the field of drive technology. The company is an experienced supplier of bevel gears, stepper gears and servo gears.

ZZ

specializes in uniform (angle gears) and non-uniform (index gears) mechanical

drives for mechanical engineering. In addition to the core products bevel gears

as standard and special gears, low-backlash servo gears and lifting spindle

gears, ZZ has also established itself as a specialist in special solutions in

mechanical and plant engineering.

ComInTec is a great partner for our company with its highly specialised product range of torque limiters, safety couplings as well as special couplings. With more than 50 years of experience in the development, optimisation and production of safety elements for drive technology, we have an excellent manufacturer at our side.

The company ComInTec S.r.l. serves our classic market segments perfectly. As a specialist for applications in the packaging systems, machine tool and plant construction, conveyor technology, transport and logistics, pharmaceuticals, foodstuffs and many other sectors, we have a very large intersection with our customers. Due to the high quality with optimal economic efficiency, we see ourselves as optimally complemented and well positioned for the future.

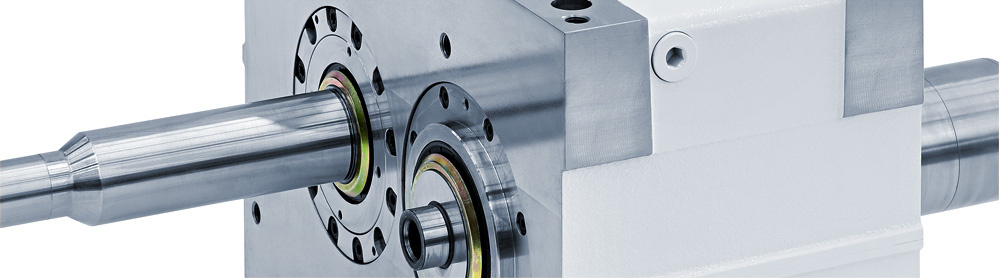

With TAS Schäfer, we have gained a market-leading partner in the field of mechanical and hydraulic friction-locked shaft-hub connections. Already in its third generation, the family-owned company develops innovative drive technology products.

Production with state-of-the-art CNC technology guarantees high-quality products. For over 60 years, the company has stood for "made in Germany". Production takes place exclusively in Germany. From its location in Wetter-Wengern, TAS Schäfer supplies customers all over the world.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de