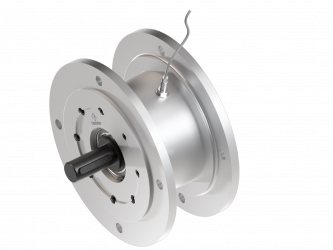

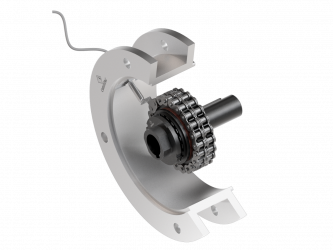

Torque limiters for reducers

Safety coupling to be mounted between the motor and gear unit thus reducing significantly the size of the device at the same power output. Available in both slip that release versions.

- Simplicity and sensitivity compared to gearbox integrated solutions

- Protect the motor-gearbox from accidental collisions or impacts from the products being processed

- Greatly reduces products on downtme in case of overload

- Absorb static torques without disengaging (friction model)

On request

- The device is already configured and ready to use

- Possibility of friction rings with different performance in the case of model slip

- Free rotation backlash free balls model according to ATEX conformity

- Possibility of surface treatments for corrosion-specific needs

Downloads

-

Torque limiter for gearboxes

(3218 KB)

Torque limiter for gearboxes

(3218 KB)

Short info

- Safety coupling made in steel fully turned, spacer made in aluminium fully turned for IEC-B5 motors

- Standard treatment of phosphating on torque limiter

- Compact solution

- Model available for IEC motors and gearboxes

- Protection in both directions

- Instant disengagement upon overload

- Fast and simple calibration

Main Applications

- Conveyor

- Packaging machines

- Wrapping machines

- Motorized systems of handling and positioning

Combination variants with coupling

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de