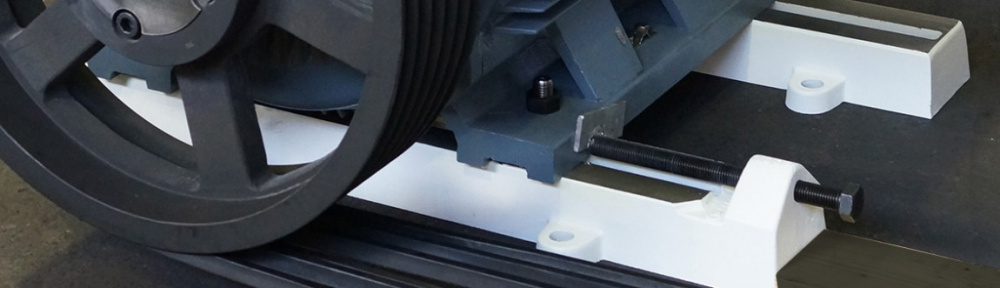

Motor bases

Motor base MW 8

Ideal for friction belt drives from 7.5 to 45 kW motors. The motor rocker can be infinitely adjusted according to the number and type of belts.

Motor base MW 10

Universal motor base for V, flat and toothed belt drives from 37 kW to 200 kW motors. Infinitely adjustable. Optimum belt tension through self-regulation.

Motor bases are an important component in drive technology. Dynamic adjustment of the belt tension to the existing load conditions or in the case of plastic expansion processes can be achieved by using a self-tensioning motor base In this case, the motor is screwed onto one of the rotatably mounted plates. The centre of gravity is then designed in such a way that the plate with the motor tends to tilt backwards. Once an inclined position of around 15° to 30° has been reached, the weight of the motor base ensures permanent and almost constant belt tension. This is very important, as poorly tensioned belts lead to increased wear on the pulley and belt as well as significantly poorer power transmission, and in extreme cases can even cause the belt to break.

Downloads

Motor bases(2054 KB)

Motor bases(2054 KB)

The application saves time and money

Motorised bases usually consist of a motor plate, supports, a pre-tensioning unit and rubber spring elements. The rubber spring element is used as a pivot bearing, which continuously compensates for belt elongation and flutter as well as excessive tensile forces when starting a drive. Normally, the corresponding mounting holes are already present in the plate. As the motor base automatically ensures that the belt tension is always correct, it is no longer necessary to switch off the system and manually re-tension it using personnel. In addition, the motor base also protects the belts from start-up overload through controlled slippage behaviour. This significantly extends the belt service life, which in turn reduces costs and energy consumption.

Perfect balance wherever it swings and vibrates

Motorised bases are used in many areas. They are often used to drive screening machines, crushers or vibrating classifiers. They are also ideal for an eccentric drive in vibrating and vibratory feeders. And drives with a constantly changing centre distance between the drive disc and the driven disc are ideally equipped with a motor base.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de