Rubber suspension units

The simple and yet compelling possibility of finding solutions to vibration and damping problems with rubber spring elements has become established in many branches of mechanical engineering.

The simple handling and ease of installation are particularly appreciated in mobile applications. All rubber springs go back to the principle of Prof. H. Neidhart. The rubber spring elements can be used in all industrial sectors. With an angle of rotation of +/- 32° and almost unlimited connection options, they are very suitable for modern, maintenance-free machine building; more and more, the elements usually take on a multiple functions such as clamping, storing, springing and dampening.

The large variety of applications for the rubber spring elements ensures constantly growing ideas as well as new fields of application. We are also happy to further develop the possible uses with our customers and, with the basic range, offer an intial starting point for demanding and sustainable solutions to complex drive problems.

Downloads

Product overview

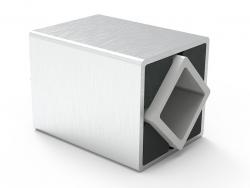

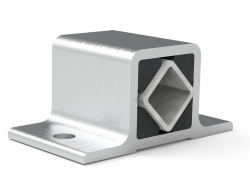

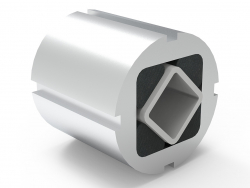

The inner profile type LTA enables fastening with screws.

Up to type LTA 7, through srews of quality 8.8 must be

used. From type LTA 8 on, there are threads in the inner

profile.

Another simple installation option is the mounting bracket type MA. On the outside, the rubber

spring element is inserted into a sleeve tube or fastened

with the mounting bracket MS.

The inner profile type LTS enables a plug-in connection.

The insertion depth of the inserted square should be at

least 1.8 times the material cross-section (dimension S).

The square should be made of bright steel with tolerance

h11 and faceted edges.

On the outside, the element is inserted into a sleeve tube or fastened with the mounting bracket type MS. An alternating deflection over the element zero position is not possible.

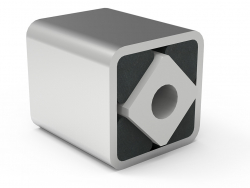

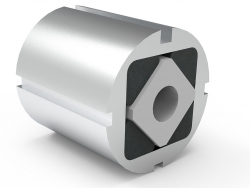

The inner profile type LTC enables fastening with central screw. Screws of quality 8.8 must be used. On the outside, the rubber suspension unit is inserted into a sleeve tube or fastened with the mounting bracket MS. Suitable for alternating deflection up to +⁄− 10°.

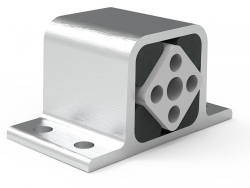

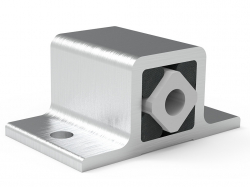

The inner profile type LTB-A allows fastening with screws.

Up to type LTB-A 7, screws of quality 8.8 must be used.

From type LTB-A 8, there are threads in the inner profile.

Another simple installation option up to size LTB-A 8 is

offered by the mounting bracket type MA.

The outer housing can be fastened directly with quality

8.8 screws through the fastening holes in the flange

section. Suitable for alternating deflection over the element

zero position.

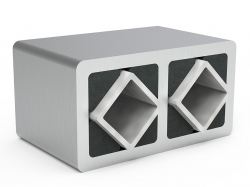

The inner profile type LTB-S enables a plug-in connection. The insertion depth of the inserted square should be at least 1.8 times the material cross-section (dimension S). The square should be made of bright steel with tolerance h11 and faceted edges. The outer housing can be fastened directly with quality 8.8 screws through the fastening holes in the flange section. An alternating defl ection over the element zero position is not possible.

The inner profile type LTB-C enables fastening with central screw. Screws of quality 8.8 must be used. The outer housing can be fastened directly with quality 8.8 screws through the fastening holes in the flange section. Suitable for alternating deflection up to +⁄− 10°

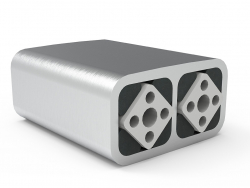

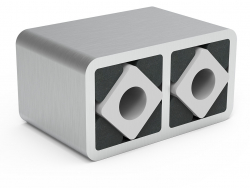

The inner profile type LTD-A allows fastening with screws.

Up to type LTD-A 7, screws of quality 8.8 must be used.

From type LTD-A 8 there are threads in the inner profile.

Another simple installation option is the mounting bracket type MA. The double element is used for the realization of series or parallel connection.

The inner profile type LTD-S enables a plug-in connection.

The insertion depth of the inserted square should be at

least 1.8 times the material cross-section (dimension S).

The squares should be made of bright steel with tolerance

h11 and faceted edges. The double element is used for

the realization of series or parallel circuits.

Only available on request.

The inner profile type LTD-C enables fastening with central

screw. Screws of quality 8.8 must be used.

The double

element is used for the realization of series or parallel

circuits.

Only available on request

The inner profile type LTK-A allows fastening with screws.

Up to type LTK 7, screws of quality 8.8 must be used.

From type LTK 8, there are threads in the inner profile.

Another simple installation option is the mounting bracket type MA. On the outside, the rubber spring element is inserted into a clamp or fastened with the mounting bracket type C.

The inner profile type LTK-S enables a plug-in connection.

The insertion depth of the inserted square should be at

least 1.8 times the material cross-section (dimension S).

The square should be made of bright steel with tolerance

h11 and faceted edges.

On the outside, the rubber spring element is inserted into a clamping fist or fastened with the clamp mounting type CK.

The inner profile type LTK-C enables fastening with central

screw. Screws of quality 8.8 must be used.

On the outside, the rubber spring element is inserted into a clamp or fastened with the mounting bracket type CK.

Your advantages at a glance

- Professional design of your application

- NO maintenance

- Large torsion angle +/-32

- Flexible connection options

- Multiple functions such as clamping, bearing, damping possible

- Precise adjustability of the clamping force

- High quality rubber compound

- Optimal advice on site

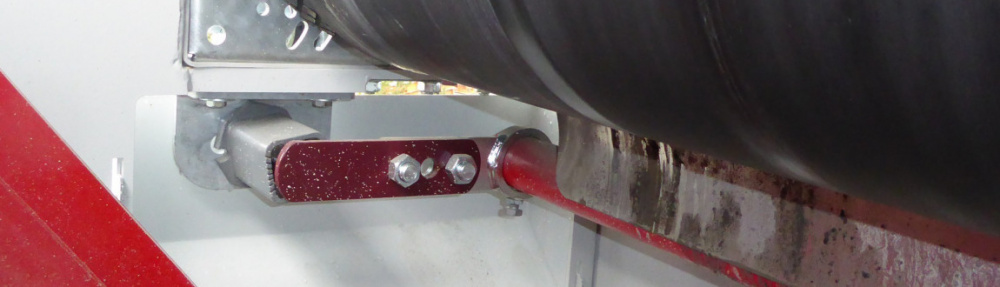

Industries and application examples

- Conveyor technology, elevators

- Road machinery and municipal vehicles

- Crushing technology

- Chippers and crushers (mobile and stationary)

- Vibrating screens

- Mill construction

- Compressors and pumps

- Agriculture

- Lift technology

- Passenger transport

Mounting options

We have the right mounting options for the right rubber spring components.

We have various standard components that are available here, which enables very

easy and flexible attachment options. Many of our customers use their own

fastening concepts and integrate the connecting parts of the spring elements

directly into their own units.

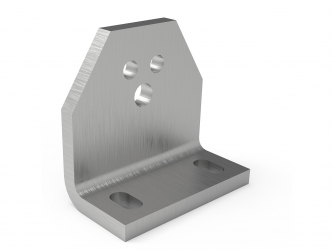

The mounting bracket type MA enables easy mounting of the LTA, LTK-A and LTD-A tensioners at right angles to the base surface.

The mounting bracket type MS allows easy mounting of the ubber spring elements type LTS, LTA and LTC. The rubber spring element type LT can be freely positioned axially in the mounting bracket type MS before tightening the screws.

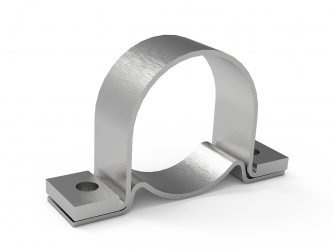

The mounting bracket type CK allows easy mounting of the REATEC rubber spring elements type LTK-S, LTK-A and LTK-C. The rubber spring element type LTK can be rotated freely in the mounting bracket type CK before tightening the screws. For this purpose, a hook wrench according to DIN 1810 can be used up to type CK 6 or, in the case of the larger types, a strap wrench.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de