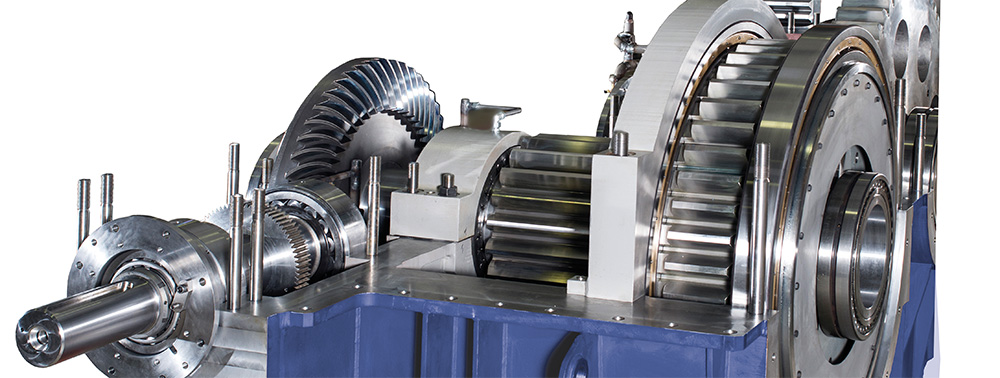

Transmission Maintenance and Repair

All manufacturers and types

In the event of machine downtime or machine failure, a quick and cost-effective solution must be found. It is important to have a competent and reliable partner for the repair, renewal and maintenance of industrial gearboxes.

We are your competent partner for all manufacturers

transmission repairs. We ensure a fast, inexpensive and professional repair, so

that your system is ready for use again at short notice. We determine the exact

cause of the damage and offer individual maintenance and service concepts.

Regardless of the manufacturer / type, we have the in-depth know-how

- Lifting gears

- Flat gears

- Large gears

- Bevel gears

- Planetary gears

- Precision gears

- Special gears

- Worm gears

- Step-driven

- Spur gears

- Angular gears

- Cycloidal gears

Downloads

Our services

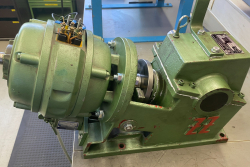

- Brand-independent repair / maintenance of transmissions

- Professional installation and removal service at the customer's premises

- Fast and professional damage analysis

- Fixed cost estimate for the repair

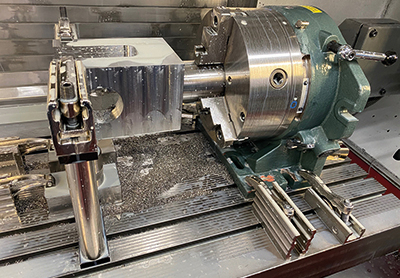

- In house mechanical production

- Using original parts or parts of equivalent quality

- Customised spare parts storage

- Balancing and alignment service

- Load tesing on our in house testing facility

- Guarantee on all of our services

- Individual maintenance and service concepts available

Fast. Reliable. Competent.

In many cases a gearbox repair is the quicker and more economical solution. You will receive an informative damage report from us with an offer. On this basis, you decide between a new gearbox or a repair.

More than 50 years of experience in the assembly of gearboxes and components speaks for itself. Our team has a lot of experience and know-how to carry out assembly and repair work regardless of the brand, type or year of manufacture. Our gearboxes are in use worldwide and are characterized by their reliability.

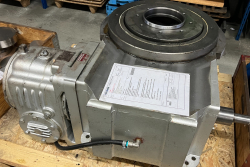

The assembly of our own

gearboxes is part of our daily business. Every move is spot on here and the

quality and performance of our employees makes us proud. We have excellent

references both for the automotive industry and in the field of classic drive

technology. We would be happy to put our options at your service.

Repair

Whether for a short-term

emergency replacement or for the comprehensive replacement of the entire drive

unit during a planned downtime:

With our modern tooling

systems, we guarantee efficient and above all safe processing of customer

orders on site or in our factory.

Our service technicians

- Failure analysis

- Transmission maintenance / renewal

- Technical modifications / optimization

- Reconstruction of transmission components

- Quality Control

- Vulnerability analysis and elimination

- Exchange transmission / spare parts

Damage Analysis

The basis of a gearbox repair is always the detailed analysis of the gearbox elements. In this way, we can guarantee high cost transparency and professional processing right from the start. In doing so, we create precise analysis of the condition of the gearbox and can thus identify problems or damage at an early stage. We develop individual concepts for you so that your system is ready for use again quickly and for the long term.

Damage assessment in detail

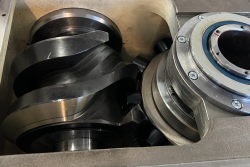

- Disassembly and cleaning of all transmission parts

- Analysis of all transmission elements

- Including all of the defective parts

- Determination of gear geometries and materials

- Creation of an error report including a cost estimate for the repair

After

approval for repairs, we refurbish the reusable components and replace the

wearing parts. Finally, the overhauled gearbox is subjected to complete checking

and test runs. In this way we can guarantee perfect function.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de