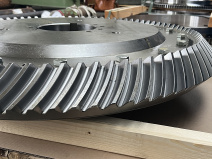

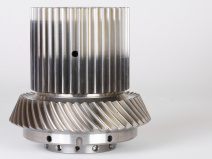

Spiral toothed bevel gears

Our bevel gears are generally manufactured according to the Klingelnberg system. We can reproduce GLEASON gears by recalculation or by final grinding. The significant improvement in pitch accuracy with 5-axis milling also provides more options when manufacturing special geometries or individual parts.

Gear grinding of hardened gears is also on the rise and ensures the repeatability and interchangeability of individual gears during production against sample gears.

Depending on the application, the gears are hardened and then hard-toothed. Lapped in pairs or ground directly, depending on requirements.

Our high-quality bevel gears enjoy an excellent reputation for their long service life and high quality. They are also used in our bevel gearboxes. They also offer optimum application possibilities in numerous customised tasks.

Downloads

-

Kegelradverzahnungen

(2836 KB)

Kegelradverzahnungen

(2836 KB)

Spiral-toothed bevel gears

| Klingelnberg cyclo-palloid | Klingelnberg HPG-S | Klingelnberg ground | Gleason ground | |

|---|---|---|---|---|

| Standard module | 1 - 20 | 4 - 20 | 1 - 12 | 4 - 12 |

| Pressure angle | 20 (17,5°) | 20° | 20° | 20° |

| Number of teeth | 6 - 120 | 6 - 120 | 6 - 120 | 6 - 120 |

| Outer diameter | < 1.400 mm | < 1.400 mm | < 900 mm | < 900 mm |

| Shaft length | < 1.800 mm | < 1.800 mm | < 900 mm | < 900 mm |

| Axle angle | 45 - 135° | 45 - 135° | 45 - 135° | 45 - 135° |

| Tooth width | < 180 mm | < 180 mm | < 150 mm | < 150 mm |

| Quality DIN 3965 | 7 - 9 | 5 - 6 | 4 - 5 | 4 - 5 |

| 5-Achs hard milled | Kurvex | |||

|---|---|---|---|---|

| Standard module | 1 - free | 1 - 10 | ||

| Pressure angle | any | 20° | ||

| Number of teeth | 6 - free | 6 - 120 | ||

| Outer diameter | < 2.800 mm | < 650 mm | ||

| Shaft length | < 2.000 mm | < 900 mm | ||

| Axle angle | 3 - 160° | 45 - 135° | ||

| Tooth width | free | < 100 mm | ||

| Quality DIN 3965 | 5 - 6 | 7 - 9 |

Further information on spiral gears according to the Klingelnberg system

- Cyclo-palloid gearing (Klingelnberg cyclo-palloid)

- HPG-S / Hard toothing (Klingelnberg HPG-S)

Straight bevel gears

| Straight tooth | |

|---|---|

| Standard module | 4 - free |

| Pressure angle | ------ |

| Number of teeth | 6 - free |

| Outer diameter | < 3.000 mm |

| Shaft length | < 2.000 mm |

| Axle angle | 3 - 160° |

| Tooth width | free |

| Quality DIN 3965 | 5 - 6 |

¹(Values and dimensions in brackets on request)

Note

Bevel gear sets according to Klingelnberg or Gleason can also be offered in a ground version.

Gleason and other geometries can be converted.

Material selection

- Case-hardening steels

- Nitriding steels

- Quenched and tempered steels

- Cast iron

- Plastics

- Stainless steels

Heat treatment

- Case hardening

- Nitriding

- Induction hardening

- Tempering

- Burnishing

Options

- Splined shaft and hub profiles to DIN ISO 14

- Splined shaft profiles according to 5480 etc.

- Polygons

- Spur gears

- Hirth gears

- Shot peening

- Coating (e.g. Balinit)

- Balancing according to DIN ISO 21490-11

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de