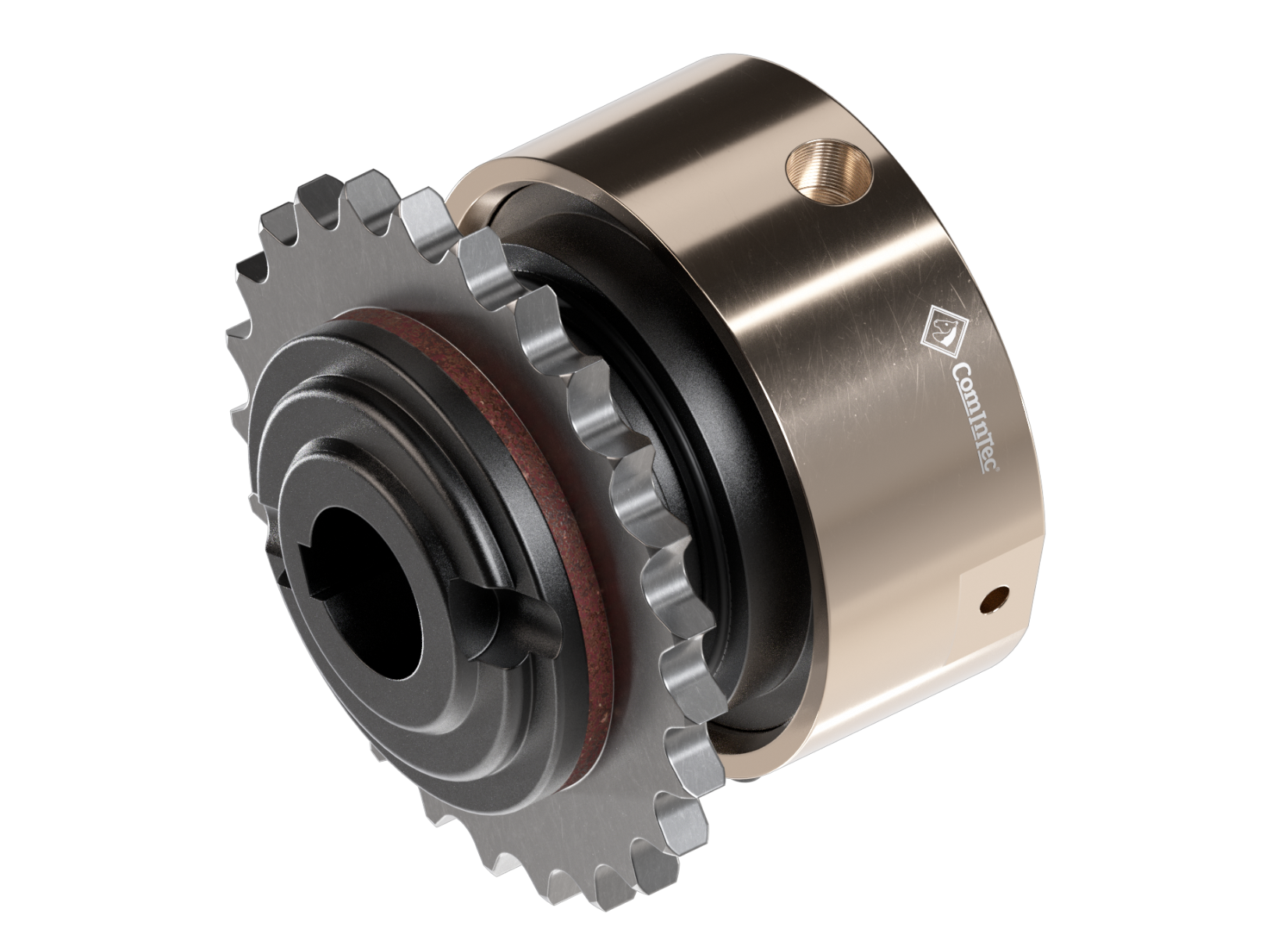

Pneumatic clutches

A friction clutch or roller with torque adjustment even during operation. Ability to disengage the drive and driven by pneumatic or electrical impulse. Low residual torque after disengagement. Calibration adjustable by changing the pressure (pneumatic) air supply.

- Engage/disengage diff erent product transmission lines

- Maintain tension of wire / film coils

- Regulate diff erent torques depending on the change of the format

- Protect the motor gearbox against every form of overload

On request

- Complete with transmission element machined and assembled (plate wheel, pulley, gear, …)

- Can be supplied with various types of rigid/elastic couplings for in-line shafts transmission

- Possibility of shaft connection with finished bore, locking assembly or other systems

- Anti-corrosive version

Downloads

-

Pneumatic clutches

(3842 KB)

Pneumatic clutches

(3842 KB)

Short info

- Simple and precise calibration

- Transmission engagement / disengagement and torque limiter functions (safety coupling)

- Reliability and repetitiveness of the calibration torque

- Torque variation whilst in motion, by pressure regulation

- Free rotation after the disengagement through a complete disconnection between the parts

- Low residual torque on disconnected parts

- Models available only with finished bore

Main applications

- Machines with variable torque requirements

- Test benches

- Coiler and uncoilers

- Cut format systems

Combination variants with coupling

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de