Worm gears

Worm gears are helical gears and where the rotary motion of a worm gear on a cylindrical shaft is transmitted to a rotating gear wheel that is offset by 90°. These gears allow a particularly high gear ratios in a confined spaces and are therefore ideal for use in tight spaces.

The worm gear consists of two components: a threaded worm shaft and a

threaded worm wheel. The worm shaft is usually made of steel and the worm wheel

is usually made of bronze.

Worm gears are high-precision and very strong offset gears. They are mainly used when a large overall gear ratio is required. With a worm gear and worm wheel, a large overall ratio can be achieved with fewer steps. This means that a smaller, less expensive gearboxes can be used.

These high-performance gears meet our requirements every time and in every

respect and are used in demanding applications such as conveyor systems, mills

and bucket elevators, extrusion machines, machine tools or separating machines.

Downloads

-

Schneckengetriebe

(1181 KB)

Schneckengetriebe

(1181 KB)

-

Standard worm gearboxes Type: S | SL | SLM

Robust, powerful, low-noise worm gear units. Grey cast iron housing. Centre offset between input and output. Nominal ratios: i= 05:1 to 83:1

-

Duplex worm gearboxes

The duplex worm gearbox is a high-precision servo gearbox for applications that require low backlash. Also for heavy-duty applications.

-

Worm gears P030-110

Precise worm gearbox with centre distances from 30 mm to 110 mm. Ratio from 1:7 to 1:99. Available as single worm gearbox or double worm gearbox.

-

Worm gearboxes and motors Series: AJ | AM | BS | C | ER

High-precision, high-performance gearboxes and motors. Modular system offers a wide range of drive solutions. Compact design. High transmission ratio in one gear stage.

Advantages

- High ratios in one gear train

- Compact design with angled drive

- High-precision, high-performance operation

- Smooth operation

- Low running noise

- High overload capacity

- Robust and rugged construction

- Self-locking possible

- Hollow shaft version possible

Areas of application

- Rotary tables and dividing heads

- Machine tools

- Grinders

- Printing machines

- Paper machines

- Reduction gearing

- Positioning and actuator drives

- Materials handling and transport technology

- Cable and elevator machines

- Mills and bucket elevators

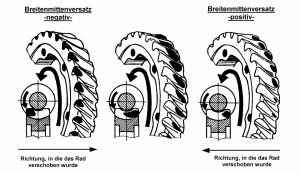

Contact pattern adjustment - accessories

FLOHR wheel sets are manufactured using the latest technology. Nevertheless, every pair of wheels and every gear is only as good as the set parameters allow. Flohr has qualified and experienced employees who ensure the performance you expect from your drive element. Regardless of whether it is a repair, a service or initial production. We also guarantee you the optimal adjustment and fit of your gear components as well as the high-quality manufacture of the components.

Repair and services

The quality of our gearboxes is an important part of our philosophy. We try to design our gearboxes according to the needs of our customers in such a way that we meet both the requirements for performance and economy.

For FLOHR, however, customer service does not end with the handover of the product. Each of our gearboxes is well documented and should give you a long service life. We also offer a full repair and maintenance service for all of our gearboxes.

In order to be able to provide any type of repair and service as quickly as possible, we offer our customers a well thought-out service strategy, which also includes the storage of special parts and a rolling exchange of strategically relevant parts. In conjunction with this, we offer a repair, maintenance and service for all of our customers' transmissions, irrespective of brand. With a quick and professional damage analysis, you will immediately receive a cost estimate for the necessary repair measures. After approval, we guarantee reliable processing of the repair or service order.

Thanks to our service strategy, we have already had very good experiences with our customers. Together with you, we agree on maintenance intervals in order to prevent damage and reduce downtimes to a minimum. However, should an unscheduled problem occur, you will be immediately supported by our team.

Talk to us about the service and maintenance concepts - we will be happy to support you with your planning!

Downloads

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de