CNC-Turning

Our

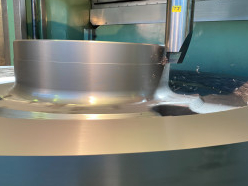

production park is equipped with different types of vertical turning centers

(carousel lathes) as well as powerful horizontal bed machines. We can machine

up to a diameter of 2,700 mm with high

performance and maximum stability.

Especially with our SCHIESS KZ250 vertical lathe, we we

are able to use the full bed swing with

the tools even for large groove profiles. The performance of this machine brings us big advantages

in time savings in the machining of our drive components.

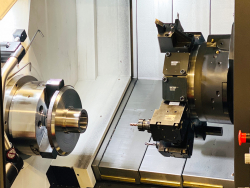

For the machining of smaller diameters, we also have a variety

of fully controlled machine tools, that provide optimum performance even for smaller

components.

Downloads

-

FLOHR Machine Overview

(771 KB)

FLOHR Machine Overview

(771 KB)

Excerpt machine overview

| Type | Manufacturer | Max. Ø | Max. lenght | Procedure |

|---|---|---|---|---|

| NEF 400 | DMG | 220 mm | 500 mm | CNC turning machine |

| VBF DUS560 | Böhringer | 250 mm | 1000 mm | CNC turning machine |

| CTX beta 1250 | Gildemeister | 250 mm | 1250 mm | CNC turning machine |

| CTX 410 | DMG | 320 mm | 600 mm | CNC turning machine |

| MT 550 | Mastrum | 460 mm | 1000 mm | CNC turning machine |

| CTX 510 | DMG | 465 mm | 1000 mm | CNC turning machine |

| L 3000 LY | HYUNDAI-WIA | 500 mm | 1200 mm | CNC turning machine, Additional spindle 22 KW |

| DV 80 | Hessapp | 630 mm | 300 mm | CNC turning machine |

| VDM 1200-11 | Hessapp | 1400 mm | 800 mm | CNC turning machine |

| DA 180 | Weiler | 380 mm | 1000 mm | conventional turning machine |

| ET BM 420 | Est Ticino | 1600 mm | 1500 mm | conventional turning machine |

| 14 DKE 100 | Schiess Froriep | 1050 mm | 800 mm | Carousel turning machine |

| 14 DKE 115 | Schiess Froriep | 1150 mm | 800 mm | Carousel turning machine |

| KSM 1400 | Schiess Froriep | 1560 mm | 600 mm | Carousel turning machine |

| SD 160 | Dörries | 1600 mm | 600 mm | Carousel turning machine |

| KZ 250 | Schiess Froriep | 2500 mm | 1500 mm | Carousel turning machine |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de