Gears

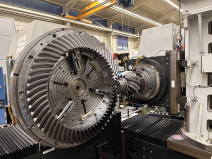

Gear components are the centrepiece of every gearbox. This is one of the core competences of FLOHR Industrietechnik. Almost every complex drive unit relies on different pairs of gears, depending on the required function, transmission ratio and performance.

For FLOHR, gears are indispensable as a transmission element. Depending on the requirements, standard pairs or customised gearing elements are manufactured. We supply complete gear units or gearing parts according to customer-specific drawing specifications.

Whether as individual specific drive elements or as a core element of our own gearboxes, the individual requirements of our customers take centre stage. Many years of experience in the use, design and optimum application of high-quality gearing elements are our great strength.

Our aim is to find the optimum solution in dialogue with our customers. Particularly in view of the constantly increasing demands on power transmission and the economic efficiency of drives, we believe we are ideally positioned to support our customers with their complex solutions.

Downloads

-

Gears: Delivery programme

(568 KB)

Gears: Delivery programme

(568 KB)

-

Spiral toothed bevel gears

We supply straight and spiral bevel gears according to the Klingelnberg system. Zyklo-Palloid, HPG-S, ground, Gleason ground, 5-axis hard-milled, Kurvex.

-

Worm gears

We supply worm gears up to an input speed of 6,000 rpm and 710 mm centre distance. Backlash-free design also available.

-

Spur gears

We supply spur gears with high quality requirements. Toothed and helical. Module 1.5 to 31. Diameter up to 2,800 mm.

-

Hirth-tooth profile (ground)

We supply Hirth serrations in hardened and ground versions. Self-centring and form-fit connection. Compact design. Up to ⌀ 1,600 mm

-

Special gears

We enable special gearing using the free-form milling process and supply splines that allow large torques to be transmitted without axial forces.

Gear types

The optimum gearing is selected depending on the requirements. In addition to the performance data, the required transmission ratio and the structural conditions also play a decisive role. The desired type of shaft arrangement and the size of the drive motor are also important when selecting the type of gearing. Our range of services includes

- Spiral arc gearing system Klingelnberg (palloid, cyclo-palloid and HPGS), Gleason and ground design

- Worm gears (standard or "DUPLEX" as high-precision, low-backlash versions)

- Spur gears

- Internal gears and special gears - ground

- HIRTH gears and crown gears

- Arrow and special gears

Increasing expectations in terms of cost-effectiveness and optimum performance are constantly setting new standards for our customers. FLOHR gears are used in our high-quality gearbox series. We use the gearings primarily for bevel gearboxes, superimposed gearboxes and screw jacks as well as other customised combinations.

Our customers include well-known companies in the fields of machine tools, textile machines, printing machines, commercial vehicles, plant engineering and general mechanical engineering.

Overview of gear types

Geometry and manufacturing options

|

Pictogram |

Type of gearing | Version | Module from - to | Ø-Max. |

|---|---|---|---|---|

|

|

Spur gearing, external gearing | Heat-treated, ground, standard according to catalogue | 1,5 up to 30 | 2.800 mm |

|

|

Internal gearing, internal teeth | Gestoßen, gefräst, bei Bedarf geschliffen | 1,5 up to 30 | 1.450 mm |

|

|

Bevel gears with spiral teeth | Klingelnberg, Gleason, free-form process, also ground | up to 13 | 1.400 mm |

|

|

Straight bevel gears | Milled, heat-treated and ground on request | up to 15 | 3.000 mm |

|

|

Worm wheels | Simplex, duplex (low backlash), multi-speed | up to 24 | 2.800 mm |

|

|

Worm shafts | Simplex, duplex, ground version, multi-start | up to 24 | |

|

|

Racks | Standard dimensions, customised heat-treated and sanded | up to 30 | |

|

|

Hirth-gears, crown gears | According to standard dimensions, ground | 8 - 720 teeth | 1.600 mm |

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8 9

9 10

10 11

11 12

12 13

13 14

14 15

15 16

16Areas of application

- Heavy engineering

- Train drives

- Conveyor technology

- Machine tools

- Other areas of drive technology

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de