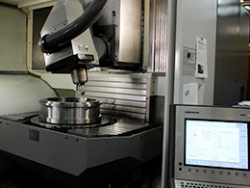

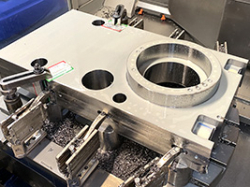

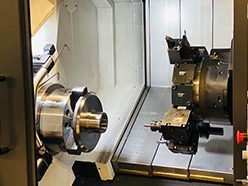

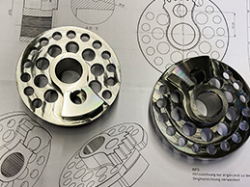

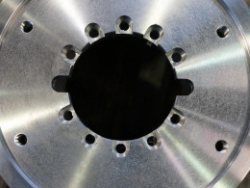

CNC-Milling / Drilling

As a manufacturer of complex production parts such as flat

cams, Globoid cams or shell and barrel cams, we are able to produce parts with

outer diameters of up to 1,800mm and heights of up to 1,400mm. All with high

production accuracy and optimum surface finish on state-of-the-art CNC

full-portal milling machines.

The manufacturing processes are suitable for the production of rotationally symmetrical bodies such as curves, as well as for complex surfaces used in tool and mould making. With a tool table clamping size of 4000 mm x 2000 mm, even large-volume production parts can be easily machined.

Our complex cam geometries are all made on our machines.

We are happy to pass on the experience we have gained in order to achieve

optimum milling results for our customers as well.

Downloads

-

FLOHR Machine Overview

(771 KB)

FLOHR Machine Overview

(771 KB)

Excerpt machine overview

| Type | Manufacturer | X-Axis | Y-Axis | Z-Axis | Procedure |

|---|---|---|---|---|---|

| RX 10 | Reiden | 1000 mm | 1100 mm | 810 mm | 5-axis CNC milling centre |

| DMU 80 | DECKEL MAHO | 880 mm | 630 mm | 630 mm | CNC machining centre |

| DMC 85V | DECKEL MAHO | 850 mm | 630 mm | 500 mm | Hard milling, CNC machining centre |

| DMU 125P | DECKEL MAHO | 1250 mm | 880 mm | 800 mm | 5-axis, CNC machining centre |

| DMC 635 | DECKEL MAHO | 635 mm | 510 mm | 460 mm | CNC machining centre |

| U 740 | Hermle | 915 mm | 500 mm | 500 mm | 5-Achsen Bearbeitungszentrum |

| U 1000 | Hermle | 1000 mm | 630 mm | 550 mm | CNC machining centre, universal milling machine |

| VTC 200 B | MAZAK | 1120 mm | 510 mm | 510 mm | CNC machining centre |

| NEXUS | YAMAZAKI | 1000 mm | 500 mm | 500 mm | CNC machining centre |

| NT 4300/1000 | Mori Seiki | 750 mm | 210 mm | 1120 mm | 5-axis CNC turn-mill centre |

| B90T | Wotan | 800 mm | 800 mm | 800 mm | Boring mill |

| VPZ 04 160/160 | SSB | 1600 mm | 1600 mm | 800 mm | CNC drilling, turning and milling machine |

| Type | Manufacturer | Max. Ø | Max. lenght | Procedure |

|---|---|---|---|---|

| KFV 600 | Präwema | 400 mm | 400 mm | Cylinder, Axial, Radial / 4-axis cam milling and grinding machine |

| KFG 500 | Präwema | 500 mm | 400 mm | Globoid / 5-axis milling and grinding machine |

| KFV 600/1 | Präwema | 620 mm | 500 mm | Axial, radial milling and grinding machine |

| P 160 | Pfauter | 150 mm | 500 mm | Spline shaft milling machine |

| ZFWVG 250/3 | WMW | 3000 mm | 300 mm | Spline shaft milling machine |

| Type | Manufacturer | Max. Ø | Max. module | Procedure |

|---|---|---|---|---|

| PE 150 | Pfauter | 150 mm | 3 | Milling machine |

| LS 252 | Liebherr | 300 mm | 6 | Milling machine |

| SN 5 | Lorenz | 300 mm | 6 | Milling machine |

| PE 300 | Pfauter | 300 mm | 8 | Milling machine |

| P 900 | Pfauter | 900 mm | 10 | Milling machine |

| 153, 180 ,173 | Koepfer | 140 mm | 10 | Milling machine |

| L 902 | Liebherr | 900 mm | 12 | Milling machine |

| 315 CNC | MODUL ZWFZ | 420 mm | 12 | Milling machine |

| P 1250 | Pfauter | 1250 mm | 16 | Milling machine |

| TSM | EGW | 1670 mm | 8 | Rack milling machine |

| L 79 | Pfauter | 2150 mm | 16 | Rack milling machine |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de