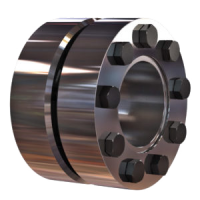

Shaft couplings

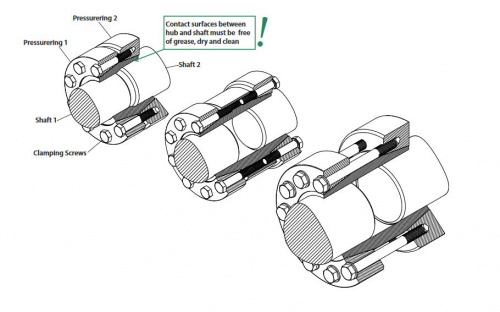

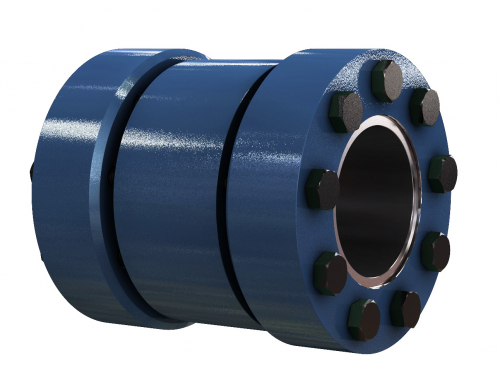

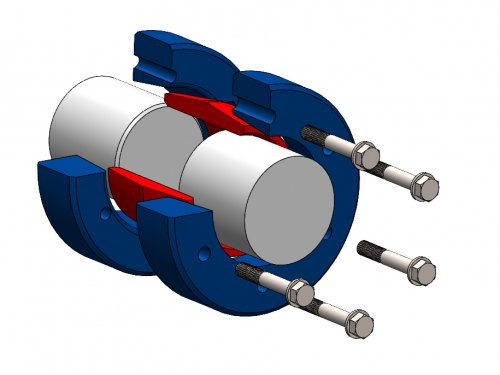

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems.

They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is.

Due to the frictional connection of the two shaft ends, torques, bending

moments and axial forces can be transmitted safely. A significant

advantage of shaft couplings is their compact design. Compared to other

shaft couplings, this is designed to be significantly smaller.

Downloads

-

Shaft couplings

(2231 KB)

Shaft couplings

(2231 KB)

Short info

- Compact Design

- Rigid and clearance-free connection of shaft ends

- Transmittable torque from 80 Nm to 1,513,000 Nm

- Shaft diameter from 10 mm to 420 mm

- Individual special solutions are possible

Product overview

Type W

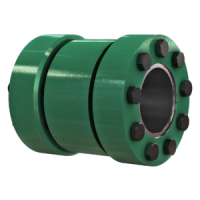

Type WLA

Type WLB

Type WK

Type W 1.4122

The most compact design is the shaft coupling of the "W" series. This is available as standard for shaft diameters from 10 mm to 270 mm. Special diameters such as inch dimensions can also be implemented without problems. Furthermore, we also manufacture our shaft couplings with improved corrosion protection and special surface finishes. If shaft ends with a larger shaft distance are to be connected to each other, the shaft couplings of the "WLA", "WLB" and "WK" series are suitable for this purpose. The connecting sleeves of these shaft couplings are specially designed for larger shaft distances and can be adapted to any customer requirement if necessary. For the marine industry, for example, we also offer shaft couplings made of stainless material (type W 1.4122).

Assembly

Compared to flexible shaft couplings, the drive or gear side of a rigid shaft coupling must be elastically supported. Due to its type of connection, the rigid shaft coupling is not able to compensate any shaft misalignment. This means that the shafts must be precisely aligned with each other before assembly. Any shocks, deformations or vibrations that occur are to be compensated by another elastically mounted part of the drive train.

The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean.

Our

rigid shaft couplings are supplied ready for installation. The

functional surfaces of the external clamping systems, threads and head

rests of the screws are provided with lubricant at the factory.

Application examples

The shaft couplings are used,

for example, in the marine industry, materials handling technology,

mixing and process technology and in the entire drive technology where a

safe and backlash-free connection of two shaft ends is required.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de