Drive belts / industrial belts

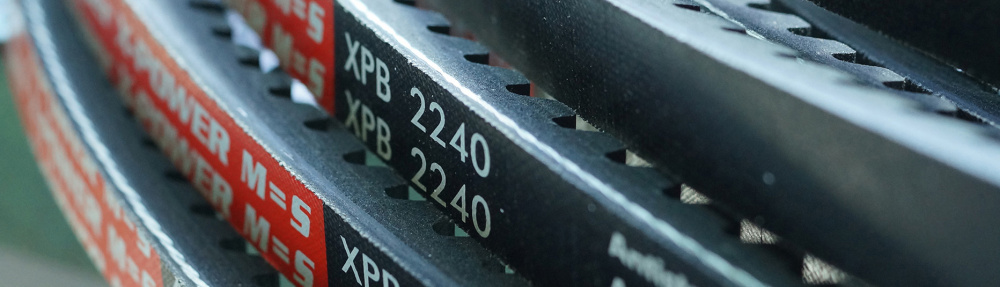

V-belts, flat belts, power belts and toothed belts

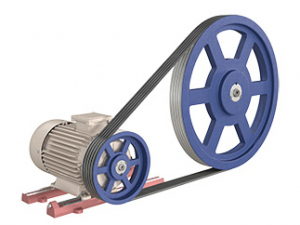

The further development of drive belts with more powerful elastomer materials has again brought the belt drive into focus as a drive solution - in the area of V-belts, flat belts and toothed belts.

Thanks to our decades of experience, we are optimally positioned to supply our customers with the perfect combination of belts and pulleys, and of course the corresponding accessories.

Regardless of whether a series drive or a complex individual drive is required - we offer the optimal solution for every application.

We work together with all of the well-known manufacturers of high-performance belts for both standard drives and customer-specific special solutions. Our team of engineers and technicians will offer you an exact solution for all performance requirements.

We would be happy to advise and accompany you from the initial design to implementation, installation and assembly as well as intelligent concepts for optimal maintenance and service of your drives.

Application examples

Downloads

-

V-belts - Drive-belts

(2142 KB)

V-belts - Drive-belts

(2142 KB)

-

Form design of belt drives

(114 KB)

Form design of belt drives

(114 KB)

- Pump and compressor construction

- Energy technology, power plant drives

- Heavy engineering - crushing plants

- Fans - axial fans

- Construction machinery and municipal vehicles

- Crushing technology (crushers, choppers, cutting mills...)

- Mill and mixing drives

Your benefits at a glance

- All profiles and geometries available

- High performance

- High belt speeds

- Reverse direction of rotation possible

- High synchronization accuracy under constant operating conditions

- Insensitive to brief overloads (slippage)

- No lubrication required

- Depending on the belt type, it is also completely maintenance-free

- Simple structure and ease of assembly

Drive design - your optimal drive

The great advantage of our drives is the absolutely performance-oriented dimensioning. We calculate your drive exactly according to the performance parameters and ensure the optimal power density. A change in the pulley geometry is always possible with little effort and without model costs for later adjustments. The flexibility of the specific drive design is also used for performance optimization. Various software systems are available for this purpose.

A team of engineers and technicians will optimally design your drive according to your requirements. In addition, we support you on site and advise you on the selection of the right drive belt.

As part of our delivery and storage concepts, we also provide personalized belts with an imprint of a logo or commission numbers, for example.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de