Steel lamina coupling

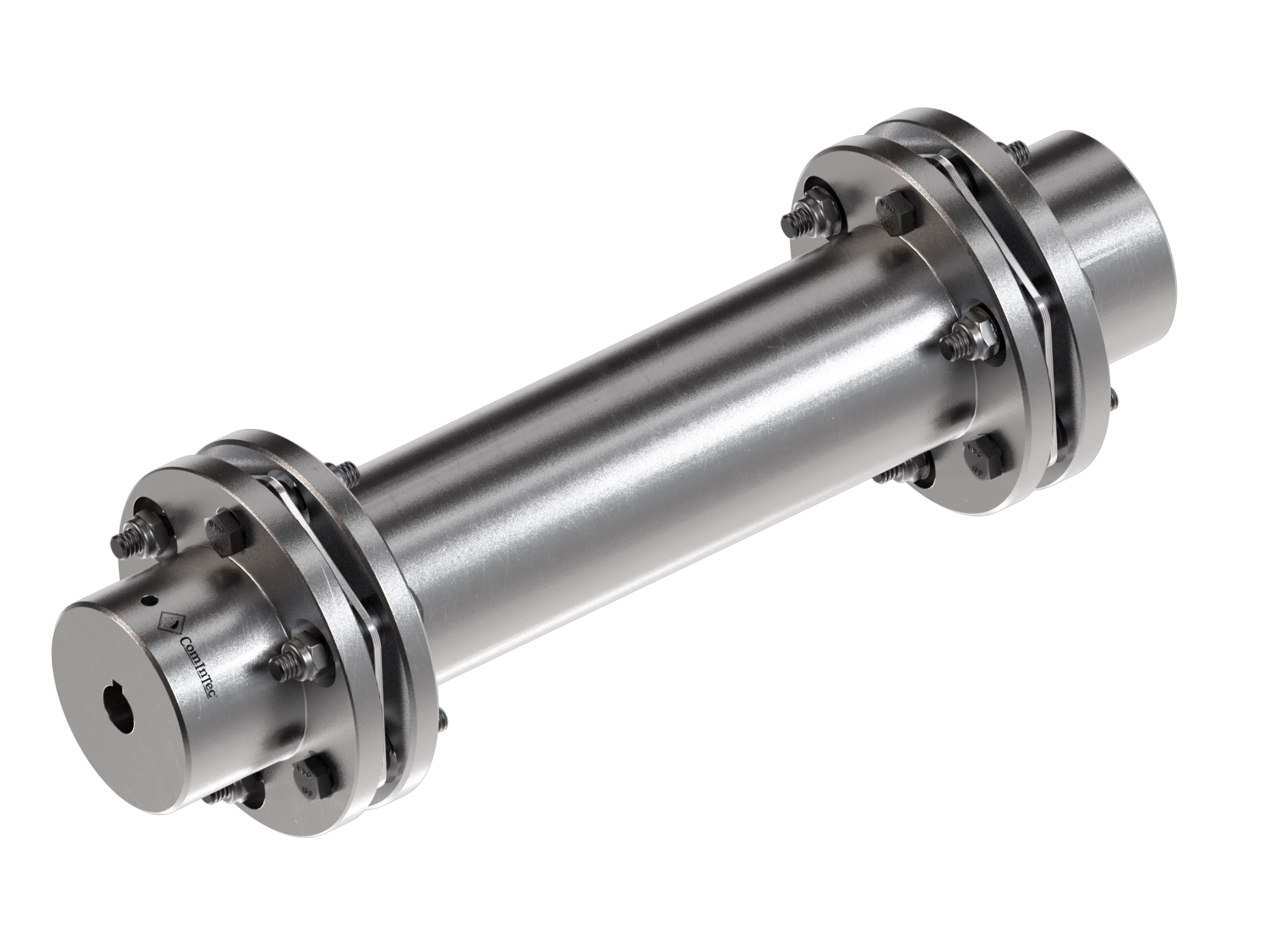

Torsionally rigid coupling

The torsionally rigid coupling GTR is designed to suit applications where high reliability, precision and an optimum weight/power ratio is required; ideally suited for applications with high speeds and power, also off ering low overhung loads when using the spacer version.

This coupling is composed of three main items: the two fully turned hubs, made in steel and the disc pack in stainless steel AISI 301 C with connection screws in steel class 10.9.

In the “double” version, there is also a spacer made to length, also built in steel UNI EN ISO 683-1:2018, fi xed between the hubs and the two disc packs.

All the components of couplings, except the spacer are made and statically balanced, before the machining of the keyway. In accordance to the specific need of the applicati on, it is possible to make static or dynamic balancing on each separate component or on the coupling, fully assembled to customer requirements.

- Use in applications with high operation temperatures (> 150 °C) possible

- Specific treatments or version in full stainless steel possible

- Reinforced couplings for specific requirements and heavy applications

- Connection to torque limiter (safety coupling) range possible

Downloads

-

Torsionally rigid coupling

(6284 KB)

Torsionally rigid coupling

(6284 KB)

Short info

- Made in steel fully turned with standard treatment of phosphating

- Disc pack in stainless steel

- High torsional rigidity

- Maintenance and wear free

- Version with double disc pack

- High torque possible

- Up to 130,000 Nm torque and 205 mm maximum bore

Description of discs

The fundamental elements of this torsionally rigid coupling are the disc packs, built from a series of stainless steel discs type AISI 304-C, connected by steel bushes.

This disc pack is connected in an alternate way to the hub flange or the eventual spacer, by using screws in steel class 10.9 and the relevant self-locking nuts.

With reference to the configuration, the disc packs can be:

- Continuous ring disc pack for 6 screws (coupling sizes 1-7)

- Sectional disc pack for 6 screws (coupling sizes 8-11)

- Sectional disc pack for 8 screws (coupling sizes 12-15)

On request

- Use in applications with high operation temperatures (> 150 °C)

- Specific treatments or version in full stainless steel

- Reinforced couplings for specific requirements and heavy applications

- Connection to torque limiter (safety coupling) range

Versions

Version with spacer GTR/DBSE

The backlash-free coupling consists of a central spacer, which varies in length according to requirements, and a double set of discs. Ideal for the connection of two driver shafts located apart.

- Made in steel and fully turned

- Galvanizing corrosion proofing

- Disk pack in stainless steel

- Maintenance and wear free

- Personalized spacer version for a specific DBSE

- Welded spacer for high torsional rigidity

STARIFLEX - Steel lamina coupling

The STARIFLEX steel lamina coupling was specially developed for applications that require reliable and maintenance-free torque transmission with simultaneous shaft displacement. With proper alignment, the couplings can be used maintenance-free and wear-free.

The three-part design of the STARIFLEX coupling enables intelligent compensation via the arrangement of the steel lamellae. The coupling can compensate for parallel displacement as well as a defined angular offset. The use of the coupling is particularly suitable for high loads and heavy stresses. Even at high speeds, the coupling is characterized by backlash-free and torsionally rigid torque transmission.

Downloads

-

STARIFLEX Stahllamellenkupplung

(649 KB)

STARIFLEX Stahllamellenkupplung

(649 KB)

Short info

- Economic efficiency with high performance

- Suitable for high speeds

- Parallel offset possible

- Defined angle compensation via steel lamellas

- Suitable for high rotational loads

- Precise and easy to mount

- Maintenance-free, wear-free

Areas of application

- Printing machines

- Pumps

- Gearboxes

- Generators

- Compressors

- Fans

- Rollers and paper / textile machines

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de