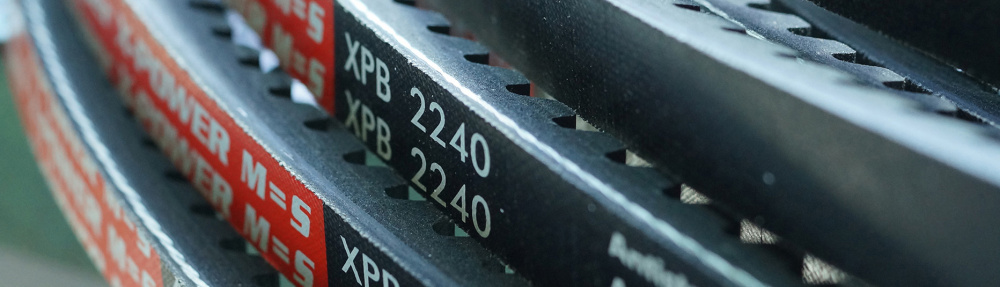

Accessories and measurement technology for drive belts

In addition to the quality of the belt, professional assembly and regular maintenance are particularly important for reliable power transmission from the drive belt.

Only a perfectly adjusted belt drive

achieves efficient performance. Accurate pulley alignment and belt tension

results in less wear on pulleys, belts, bearings and seals. The vibration

intensity is also reduced. More efficiency also means lower energy costs. The

measuring tools pay for themselves within just a few months.

Your advantages at a glance

- Professional tools for assembly, maintenance and control

- Long service life of the belt

- Safe plant operation through reliable verification results

- Ease of use

- Different designs depending on the intensity of use

Downloads

-

Measurement technology for drive belts

(2985 KB)

Measurement technology for drive belts

(2985 KB)

-

LüCo LaserPro©

The practical LüCo LaserPro© alignment laser makes it easier to fit the drive belt and is helpful for professional maintenance documentation.

-

LüCo TensionPro2©

The belt tension meter or trummeter enables the belt tension to be measured professionally and quickly. Safe and efficient system operation.

-

LüCo Service-Kit

We stock professional tools and equipment for aligning pulleys, including measuring and setting the optimum belt tension.

Use of vibration dampers and belt tensioners

The tension roller drive is used with small center distances and large transmission ratios when the open belt drive can no longer be used due to the small angle of contact of the small pulley. A tensioning pulley is inserted into the slack side, which tensions the belt with its own weight, tensioning weights or spring force.

More information on vibrationdampers and belt tensioners.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de