Rollers, chain riders and sprocket wheels

Elements for specific combination with the TE tensioner device

The addition there are universal clamps that are geared to

a specific applications. In order to ensure the most economical solution

possible, we have a standard range of additional components that can be mounted

directly onto the universal clamp. The units are delivered assembled and can be

individually combined. In the case of heavily loaded units, individual bearings

can also be fitted.

Advantages

- Professional design

of your rubber spring unit

- High performance

through quality

- Simple,

streamlined fit

- Connection

dimensions variable

- Wear resistance

of the elements

- High quality

bearings and components for long service life

- Optimum

price/performance ratio

Downloads

-

RESATEC rollers

(2198 KB)

RESATEC rollers

(2198 KB)

-

RESATEC sprocket wheels

(2248 KB)

RESATEC sprocket wheels

(2248 KB)

-

RESATEC chain riders

(2344 KB)

RESATEC chain riders

(2344 KB)

Product overview

Initially developed as a rotating pulley for tensioning fl at belts and later for tensioning poly and V-belts as well as power belts, the roller type RE is widely used as a universal machine component. Would you like adaptations in material, diameter or shape? Please clarify the possibilities with us

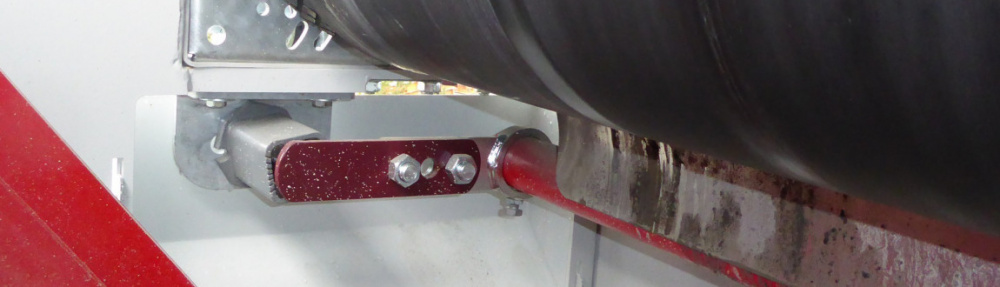

For the tensioning of chains with low running speed

(continuous operation up to 1.5 m/s) the chain rider type

CR can be used. The high quality plastic material does not

require any lubrication. Due to the unique design, the

chain always encloses the rider in such a way that

problem-free guiding of the chain is ensured.

The chain rider type CRS is supplied as a set with the appropriate assembly material for the corresponding tensioning element.

The chain rider type CRD is supplied as a set with the appropriate assembly material for the corresponding tensioning element.

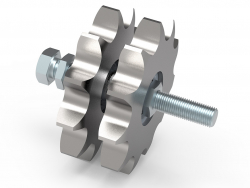

For the tensioning of chains we offers a range

of sprocket wheels matching the RESATEC tensioner

devices. Shown is the sprocket wheel type K.

Packed in the sprocket set type KS-Simplex the sprocket wheel is supplied with the appropriate assembly material for the corresponding RESATEC tensioner device.

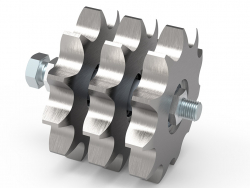

Packed in the sprocket set type KS-Duplex the sprocket wheel is supplied with the appropriate assembly material for the corresponding RESATEC tensioner device. Including the corresponding spacer sleeves for the correct guidance of the chain track.

Packed in the sprocket set type KS-Triplex the sprocket wheel is supplied with the appropriate assembly material for the corresponding RESATEC tensioner device. Including the corresponding spacer sleeves for the correct guidance of the chain track.

Application examples

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de