Hydraulically tensionable products

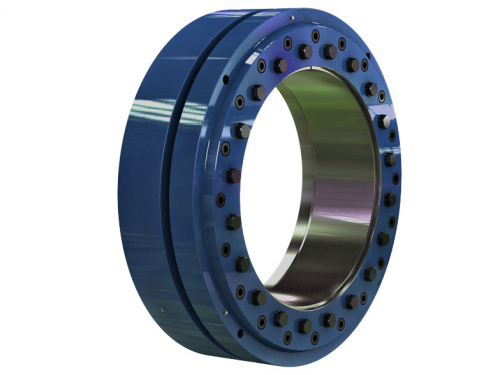

Hydraulically tensionable shrink discs are used when shaft and hub have to be connected safely and quickly. They are particularly suitable for assembly on test benches and repetitive clamping operations. Furthermore, the SHS series impresses with its unique selling points, such as low pressure required for clamping, customer-side performance of maintenance and repair work, and the possibility of adapting the inner ring to different sizes.

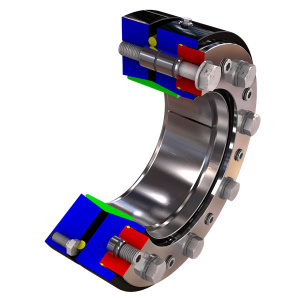

The main function of a hydraulically

tensionable shrink disc is therefore to securely connect a shaft to a

hub by means of a frictional connection. For example, between a drive

shaft and a hollow transmission shaft.

The hydraulically tensionable shrink disc creates a backlash-free

connection by pressing the hub onto the shaft. This type of connection

is mainly used to transmit torque. The shrink disc of the "SHS" series

only provides the required forces and does not itself transmit any

forces or torques between the shaft and hub. It is therefore not in the

flow of forces. In the SHS, the basic principle of the mechanical,

three-part shrink disc has been retained. This principle has been tried

and tested for a long time. Here, the force-transmitting friction

surfaces are strictly separated from the hydraulic system. This strict

separation prevents oil contamination of these surfaces.

The benefits

- Application specific design / customization

- Rapid tightening and loosening in comparison with mechanical shrink discs

- Inner ring can be adapted to different sizes

- Maintenance and repair feasible customer-sided

- Transmission of high torques

- Relatively low pressure

- Maintenance and repair can be carried out by the customer

- Low follow-up costs

Product overview

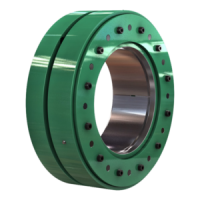

Standard SHS

_________________

140 - 1.000 mm

20 - 10.000 kNm

Up to 180 bar

Bench SHS

_________________

140 - 1.000 mm

20 - 14.000 kNm

Up to 200 bar

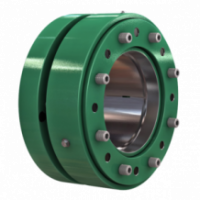

Marine SHS

_________________

140 - 800 mm

14 - 2.800 kNm

Up to 200 bar

Wind power SHS

_________________

140 - 1.000 mm

20 - 12.000 kNm

Up to 200 bar

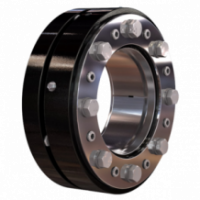

Special version

_________________

100 - 1.000 mm

10 - 12.000 kNm

Up to 200 bar

The biggest advantage of the hydraulic tensionable shrink disc like the SHS series is the enormous time saving during assembly. This system can already be clamped with low pressure between 120 bar and 200 bar and thus reduces the assembly times considerably. The reduction of this time increases exponentially with the diameter. For larger diameters, e.g. 530 mm, a hydraulically tensionable shrink disc of the "SHS" type is already tensioned after a few minutes.

This compares with an

assembly time of several hours for a mechanical shrink disc. The time

required and the physical strain on fitters and maintenance personnel

can therefore be significantly reduced. Even after a long service life

of several years, when, for example, seals no longer function depending

on their location, the hydraulically tensionable shrink disc of the

"SHS" series can be dismantled in the same way as a mechanical shrink

disc. This is done by loosening the screw connection and without further

pressure application.

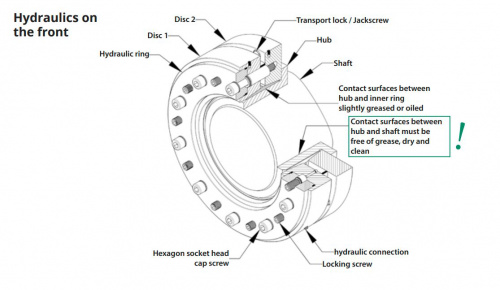

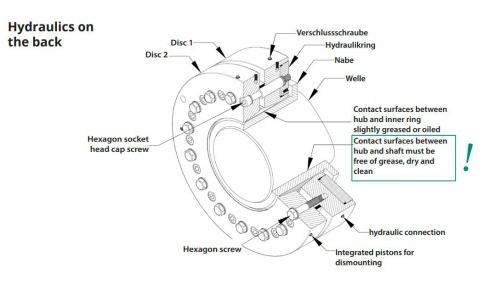

Assembly

It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the hydraulik system. By using conical surfaces the inner diameter reduces and the radial pressure is built up. After clamping the SHS will be locked mechanically and the hydraulic pressure will be removed. Due to this simple approach the SHS is suitable for repetitive clamping operations as they occur on a test bench, for example.

To achieve proper operation and to a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be free of grease, dry and clean. The functional surfaces of the shrink disc are equipped at the factory with lubricant. The contact surfaces between the hub and shrink disc must also be provided with grease before installation.

Application examples

The use of clamping sets is diverse and covers various industrial sectors. From classic mechanical engineering, as well as conveyor and drive technology, to the packaging and food industries. The clamping sets enable precise fastening of hub heads on shafts or axles, for example when fixing toothed wheels and sprockets.

In the food and petrochemical industry, stainless steel versions of the clamping sets are often used in filling or agitating systems. Clamping sets are used in the packaging industry to fix pulleys and to transport objects within the machine.

Further application examples according to model variant:

Standard: Industrial gearboxes, Hollow shaft gearboxes, Hydraulic motors

Test bench: Gearbox test stands

Marine: Wave systems

Wind energy: Main rotor shaft, Generator shaft

Customized: Chrusher, Mills, Conveying technology ...

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de