Tool changers

for multi-tool / robotic applications

DESTACO automatic tool changers are perfect for flexible, multi-tool applications which use only one robot. These products were designed with exceptional repeatability, high rigidity and load capacity to make them ideal for any robotic application. End effector tooling and modular fixturing can be automatically changed, quickly and easily, to accommodate many different styles of parts in the same cell or machine.

Markets

- Aerospace

- Automotive

- Food and Packaging

- Industrial

- Consumer Goods

Applications

- Stamping

- CNC Machining

- Plastic injection molding

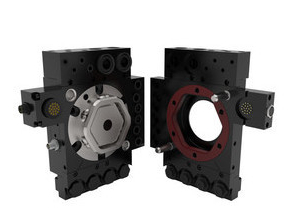

Automatic tool changers – Series QC | TP

Destaco’s QC & TP Series of EOA modular robot tool changers lead the industry with a full product line covering up to 1200 lbs (545Kg). A wide variety of utilities are available to quick disconnect, I/O, air, water, weld power, servo power, vacuum lines. These models feature a simple locking mechanism that comes with a lifetime warranty, the best weight to payload ratio in the industry, and hard anodize for improved wear over long periods.

| Product | Max. Workpiece weight (lb) | Weight (lb) | Max. Torque (in-lb) | Configuration |

|---|---|---|---|---|

| QC-150 | 150 | 4,80 | 1.900 | Robot side |

| QC-30 | 30 | 0,50 | 200 | Robot side |

| QC-60 | 60 | 1,90 | 780 | Robot side |

| TP-150 | 150 | 2,20 | 1.900 | Tool side |

| TP-30 | 30 | 0,25 | 200 | Tool side |

| TP-60 | 60 | 0,90 | 780 | Tool side |

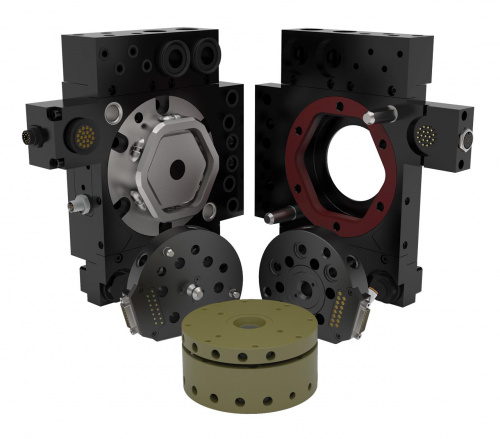

Modular robot tool changers - Series RQC | RTP

Destaco’s RQC & RTP Series of modular robot tool changers lead the industry with a full product line covering up to 1200lbs [545Kg]. A wide variety of utilities are available to quick disconnect, I/O, air, water, weld power, servo power, vacuum lines. These models feature a high level of flexibility accommodating up to 4 optional modules to be picked up among a wide choice, 6 patented roller mechanisms that provide a low stress and highly rigid locking capability, and accommodations for the two halves to couple and to be safe in case of air failure.

| Product | Max. Workpiece weight (lb) | Weight (lb) | Max. Torque (in-lb) | Configuration |

|---|---|---|---|---|

| RQC-1200 | 1200 | 14,10 | 30.000 | Robot side |

| RQC-200 | 200 | 4,70 | 7.200 | Robot side |

| RQC-400 | 400 | 8,00 | 14.000 | Robot side |

| RQC-800 | 800 | 11,80 | 22.000 | Robot side |

| RTP-1200 | 1.200 | 4,20 | 30.000 | Tool side |

| RTP-200 | 200 | 2,00 | 7.200 | Tool side |

| RTP-400 | 400 | 2,40 | 14.000 | Tool side |

| RTP-800 | 800 | 4,00 | 22.000 | Tool side |

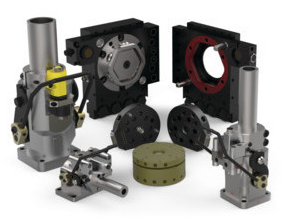

Manual tool changers

Destaco´s manual tool changers, in cooporation with automation adapters and press nest stands, allow you to quickly switch between various end effector tooling in seconds with the pull of a handle. Optional integral air ports and electric connections provide immediate power to your system, eliminates manual re-connection of air lines or electric plugs, and reduces machine downtime.

| Product | Tube Diameter (in) | A-Side | B-Side |

|---|---|---|---|

| CPI-RDH-F19S-B19 |

|

19-Pin | 19-Pin, Male Plug, Female Socket |

| CPI-RDH-F16S-A19 |

|

19-Pin | 16-Pin, Male Plug, Female Socket |

| CPI-RDB-M10P-A10 |

|

10-Pin | 10-Pin, Male Pin, Female Plug |

| CPI-RDN-10 | 1, 0.98 |

|

|

| CPO-RDH-F10S-B10 |

|

10-Pin | 10-Pin, Male Plug, Female Socket |

| CPI-RDC-1510 | 1 |

|

|

| CPI-RDC-60 | 2.36 |

|

|

| CPI-RDB-M10P-B10 |

|

10-Pin | 10-Pin, Male Pin, Female Plug |

| CPI-RDC-25M | 0.98 |

|

|

| CPI-RDH-F19S-A19 |

|

19-Pin | 19-Pin, Male Plug, Female Socket |

| CPI-RDB-M19P-B19 |

|

19-Pin | 19-Pin, Male Pin, Female Plug |

| CPI-RDC-40 | 1.57 |

|

|

| CPI-RDC-25 | 2.5 |

|

|

| CPI-RDB-M19P-A19 |

|

19-Pin | 19-Pin, Male Pin, Female Plug |

| CPI-RDC-15 | 1.5 |

|

|

| CPI-RDC-10 | 1 |

|

|

| CPI-RDB-M16P-A14 |

|

14-Pin | 16-Pin, Male Pin, Female Plug |

| CPI-RDN-25-6 | 2.36, 2.5 |

|

|

| RTP-800 |

|

19-Pin | 16-Pin, Male Pin, Female Plug |

| CPI-RDB-M16P-A19 | 1.5, 1.57, 1 |

|

|

| CPO-RDH-F10S-A10 |

|

10-Pin | 10-Pin, Male Plug, Female Socket |

| CPI-RDH-F16S-A14 |

|

14-Pin | 16-Pin, Male Plug, Female Socket |

Manual tool changers – Series TC1

Destaco’s TC1 Series tool changers are ultralight, compact, and ideal for cobot work cells and applications requiring custom coupling solutions. Designed for safety, ease of use, durability, and excellent repeatability, this tool changer features a very low profile and a coupling solution with pneumatic and electrical pass-thru capability. The tool changer features IS0 9409 mounting, plus a highly adaptive blank version that is easily modified by machine builders for application specific needs.

-

Destaco Series TC1

(1429 KB)

Destaco Series TC1

(1429 KB)

| Product | Max. Workpiece weigh (lb) | Max. Torque (in-lb) | Weight (lb) |

|---|---|---|---|

| TC1-050-T-01 | 22 | 885 | 0,44 |

| TC1-050-M-01 | 22 | 885 | 0,44 |

| TC1-050-M-00 | 22 | 885 | 0,44 |

| TC1-050-T-02 | 22 | 885 | 0,44 |

| TC1-050-T-00 | 22 | 885 | 0,44 |

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de