MALMEDIE Safety couplings

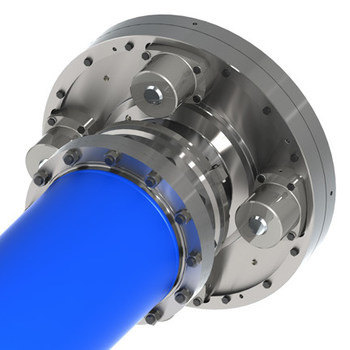

Proven under very difficult application conditions, the function of MALMEDIE safety couplings is characterised by high precision of disengagement recurrences and rapid easy reset!

Thus the drive components of equipment can, on the one hand, be effectively protected from damage due to overload, and on the other hand lost production time can be significantly reduced. Unlike shear pins or shear rings, the safety-elements are not destroyed when disengagement is triggered, and can quickly be reactivated with the simplest tools, such as a hammer.

If needed, two or more safety-elements can be used for form-fitted and tensionally locked connection of two coupling flanges.

Optional automatic re-engagement is availale.

Downloads

-

Malmedie Safety couplings

(1501 KB)

Malmedie Safety couplings

(1501 KB)

Main applications

- Rolling Mills

- Metallurgical Industry

- Mining

- Chemical Industry

- Container Cranes (SOS)

Main applications

- The possible variation in the number and size of the safety elements and of the effective diameter means that the maximum release (shut-off) torque can be selected almost without limit.

- The individual safety element cannot be overloadedif correctly chosen.

- Exsisting shear-pin couplings can be replaced by MALMEDIE Safety-Couplings.

ATEX

II 2 G T4/TS/T6 -20°C <= Ta <= +65°C/+55°C/+40°C

II 2 D T100°C

| Size | Shut-off force / safety element (N) Fu min | Shut-off force / safety element (N) Fu max |

|---|---|---|

| 10 | 5.435 | 13.180 |

| 20 | 15.700 | 36.724 |

| 30 | 81.853 | 185.264 |

| 40 | 264.838 | 511.542 |

Overriding features of the safety couplings

- High load capacity / robust design

- High switch-off accuracy

- Quick and easy re-engagement (also remote controlled)

- Maintenance-free / long service life

- Low costs due to short downtimes

- Suitable for reversing operation

- Releasing

- Optionally with automatic wear indicator

- Suitable for use in potentially explosive atmospheres according to RL 94/9/EG

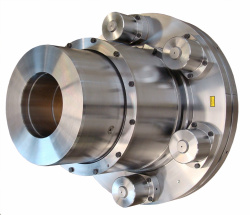

Quality and Manufacturing

All safety coupling parts are manufactured according to

strict internal quality control procedures. Modern CNC manufacturing technology

ensures the interchangeability of individual parts. All power-transmitting

clutch parts are made of high-quality heat-treated steel. Wear is reduced

through the precise selection of materials and appropriate hardening processes.

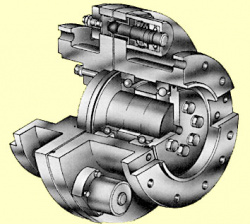

Structure and Characteristics

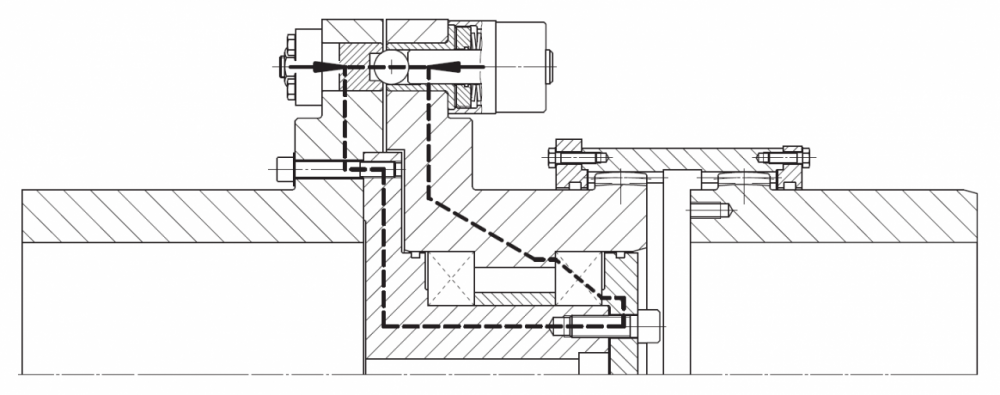

When the safety overload process is triggered, the safety assemblies are not destroyed and can be quickly reactivated using simple tools such as a plastic hammer. In contrast to shear pins or shear rings which need to be replaced. Depending on requirements, two or more safety assemblies can be used for the connection of the two coupling flanges. Despite their compact design, the safety assemblies transmit more than adequate axial torque when they are engaged.

Axial forces. These must be absorbed by a special, precise and stable bearing arrangement

on the two coupling flanges and must kept

away from the connected drive parts - such as motor, gearbox, etc.

The MALMEDIE safety couplings are suitable for use in forward

or reverse operation. Due to the complexity of the applications, MALMEDIE

safety couplings are almost exclusively adapted to customer requirements. Only

the safety elements are standard parts.

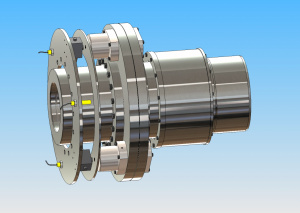

Design, calculation

Each

safety coupling is controlled with high precision due to the design of the

safety elements. The design and calculation of the coupling is done specifically

according to your application. Alternatively, you can of course select the

suitable element from our programme. We will be happy to support you in the

selection of the coupling.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de