Worm and worm wheel gears

Worm gearboxes are

mainly used for large ratios, low speeds and high torques. The proportion of

sliding is very high with this type of gearing. Our manufacturing accuracy for

the worm gear sets is in the range of DIN 3695-4. Due to different modules (profiles)

on the two flank sides of the tooth profiles, the tooth thickness changes over

the worm gear shaft. An axial displacement of the shaft in the worm wheel

allows the backlash to be adjusted almost to the point of "no

backlash". The gearing can be adjusted at maintenance intervals to ensure

optimum transmission.

Duplex gearing is

especially used in applications needing the highest precision. Many of our

customers come from precision mechanics so install the worm wheel sets in

positioning units or machine tools. In-house, the DUPLEX gears are used for

rotary indexing tables, dividing heads and combination applications.

In addition to the standard program

in the catalogue, a large number of customer-specific designs are manufactured

up to a center distance of 710 mm. A large warehouse and maximum flexibility in

production also allow just-in-time delivery. Depending on the customer

requirements, a wheel set calculation is carried out. Translations can be

calculated and manufactured at the factory. It is not always possible to use

existing gear cutting tools.

Advantages

- Ideal for high precision requirements

- Quiet running

- Low vibration

- Backlash: < 1 Arcmin. (0.016°)

- 10 sizes: 35 to 200

- Input speed up to 6,000 rpm.

- Up to 710 mm center distance

Self locking

Dynamic

self-locking

max.

3° helix angle with grease lubrication

max. 2.5° helix angle when lubricated

with synthetic oils

Static

self-locking

from 3° to 5° helix angle with grease lubrication

from 2.5° to 4.5° helix angle when

lubricated with synthetic oils

There is no self-locking at pitch

angles of more than 4.5° or 5°. In addition, some factors can negatively affect

self-locking. If there are shocks or vibrations, there is the possibility that

the self-locking function will be lost.

Factors influencing self-locking

- Pitch Angle

- Surface roughness of the flanks

- Sliding speed

- Lubricant

- Heating up

Factors influencing efficiency

- Helix angle of the worm gear

- Surface finish

- Sliding speed

- Lubricant

- Installation conditions

Applications / Industries

Our gearwheel sets and gearboxes are used worldwide in a wide variety of industries and drive trains.

Examples are: Energy technology,

elevator technology, actuators, positioning tables, machine tools, lifting

systems and stage technology and also in other areas of application for general

drive technology.

Materials

Our many years of experience in the development and calculation of the drives are supported by well-known raw material suppliers. With the raw material, we carefully select the alloy composition for the respective application. Material certificates and material test certificates are readily available on request.

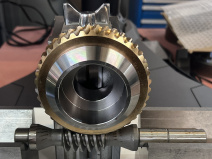

The worm shaft is made of

case-hardened steel. The flanks and bores are ground. The worm wheel is made of

bronze. Here, too, the customer can work with us to find the best selection for

the desired application.

Cu Sn 12 DIN 1705

Soft material with good wear

resistance for high sliding speeds.

Cu Sn 12 Ni DIN 1705

Other materials on request.

Soft

material with a high wear resistance due to the addition of nickel, suitable

for high sliding speeds

Plastic wheels can also be used. It should be noted that due to the poor thermal conductivity, it should only be used for low sliding speeds <1.5 m/s and medium tooth flank loads. The worm must be hardened and the flanks must be ground.

Plastic worm gears may be operated

with approx. 50% torque load of the bronze gears (MF mineral grease

specifications).

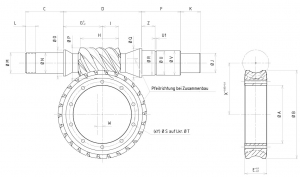

DUPLEX system - backlash-free design

The DUBLEX system is a special version with reduced, adjustable backlash. The technical design of the DUPLEX

worm gear sets is based on the fact that both the worm shaft and the worm wheel

have different modules (profiles) for the left and right flank. With this

technology, the worm profile becomes stronger from pitch to pitch, so that

there is a reduction in play through axial displacement of the worm. The axial

displacement of the worm shaft is carried out either by a special adjustment

adapter available from the catalogue or by appropriate adjustment devices supplied

by the customer.

Assembly and installation

When installing and adjusting wheel sets, care must be taken to ensure that the contact pattern of the gearing is adjusted correctly.

By checking the position of the

contact pattern when installing, you can see whether there is an error regarding

the axial position of the worm wheel. The contact pattern should tend towards

the outside side if possible. If the direction of rotation changes (reversing

operation), the contact pattern should tend towards the middle.

1

1 2

2 3

3 4

4 5

5 6

6 7

7 8

8Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de