Screw jacks / lifting systems

Screw jacks as a classic drive element for linear movements are offered both with trapezoidal thread spindles and with rolled or ground ball screws.

Our

gear housing allows oil lubrication and therefore high lifting speeds even with

a trapezoidal thread spindle. The range of sizes varies between a lifting

capacity of 5 kN and 1000 kN. With our comprehensive and functional accessories

you can expand your system to a complete system. We can advise you individually

and plan the lifting system according to your needs.

PDF Download

-

Spindelhubgetriebe

(1882 KB)

Spindelhubgetriebe

(1882 KB)

-

Spindelhubgetriebe Bauart N

(1421 KB)

Spindelhubgetriebe Bauart N

(1421 KB)

-

Anfrageformular Spindelhubgetriebe

(271 KB)

Anfrageformular Spindelhubgetriebe

(271 KB)

Depending

on the application, we can use our standard range or design a complex special

solution for you. The ability to buy cheap series drives as well as to

implement highly stressed and precise drive elements through in-house

production give us many opportunities to offer you an optimal lifting unit.

Product overview

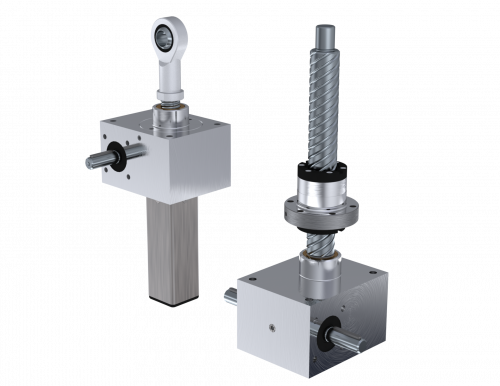

Worm gear screw jacks|Series N

The cubic-type screw jacks of series N are lifting elements that have enjoyed great popularity among users for decades due to their shape and characteristics. The screw drives from our own production, paired with high-quality worm gearboxes, result in screw jacks with outstanding properties in terms of lifting power and smoothness.

The lifting gear units are available with trapezoidal or ball screw drive with lifting forces from 150 to 500kN. The cubic design enables the use of the screw jacks in all mounting positions. As an N version with continuous spindle or as an R version with rotating spindle in combination with a running nut, the screw jacks can be assembled for the respective application. As a further expansion stage, the lifting elements in the N version can be supplied non-rotating by means of a square protective tube or V-groove.

By connecting individual screw jacks with drive shafts lifting systems can be realized in a simple way. With the rich accessories many problems can be solved with the standard program.

The screw

jacks of the N series include 11 sizes from 2.5 - 500 kN lifting force with

stationary and rotating spindle.

- Some screw jack sizes are with a lifetime lubrication as standard

- Significantly improved efficiency through optimization of tolerances and surface quality

- Limited absorption of lateral forces by using the trapezoidal screw drive

- Delivery optionally with ball or trapezoidal screw drives

- Can be mounted in any position due to the cubic design

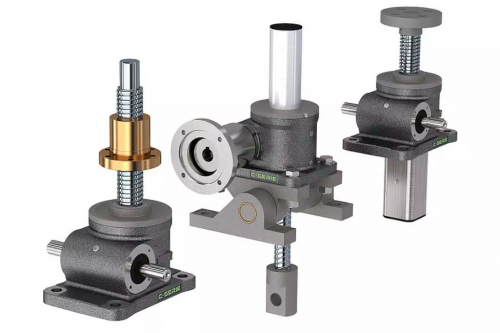

Classic worm gear screw jacks|Series C

The classic screw jacks of series C prove to be modern high-performance screw jacks. This is insured not only by the integrated screw lubrictation, making a relubrication of the spindle drive during operation possible, but also by the high-performance gearing, that allows higher efficiency and longer duty cycles. Due to the separated lubrication systems of gear and screw jacks the new C-series screw jacks can be used in any desired installation position. They are provided with a high quality semi-fluid grease and lubricated for life unter normal circumstances.

Various spindle types and pitches can be freely selected

in the standard range. In addition to single and multi-start trapezoidal thread

spindles, ball thread spindles with different pitches can also be used. In the

version with a stationary spindle, the nuts are compactly integrated into the

gear housing. This saves installation space. Special designs, special sizes and

special materials are possible on request.

- Technically robust and flexible in use

- Integrated spindle

lubrication, even possible during operation

- Heavy-duty gearing that

enables higher efficiencies and longer duty cycles

- Separate lubrication circuits

for gearbox and spindle

- Can be used in any

installation position

- Lubricated for life under normal operating conditions thanks to special high-temperature fluid grease

- The FEM (Finite Element Method) optimized housing enables

safe use even with the highest loads.

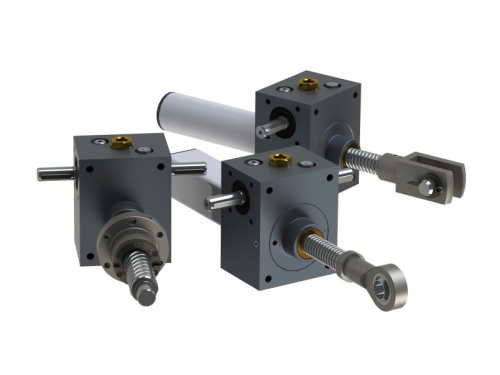

High speed screw jacks|Series S

The high-speed gearboxes supplement the range of screw jacks for extended applications with greater dynamics. Its application range is in the middle load range (12.3 kN - 117 kN). High-speed gearboxes have hardened and ground, spiral-toothed bevel gear ratios. You achieve high lifting speeds while improving efficiency.

The three sizes G1, G2 and G3 are available both as N-version with stationary, continuous spindle, as V-version protected against twisting and as R-version with rotating spindle. The 2: 1 and 3: 1 gear ratios in conjunction with high pitch ball screw spindles enable high dynamic drive solutions.k.

With ball screw spindles, high speed screw jacks achieve even better performance. All high speed screw jacks are functional in any position and can be mounted on all sides thanks to the cubic design. Depending on the application, the gear units are supplied with up to four drive shafts, so that additional bevel gear drives may be omitted. All high speed screw jacks are filled with oil at the factory.

High performance screw jacks|Series NA

Our High Performance Worm Gear Screw Jacks of the NA-Series are convincing of an optimized worm gear associated with a higher efficiency and longer duty cycles. By separating the gear lubrication from the spindle lubrication the NA-Series can be run with an input-speed up to 3000 1/ min. The case-hardened and grounded worm gear guarantees maximum drive torques and fatigue fracture strength.

The program

includes 6 sizes from 5 to 350 kN lifting force with stationary, non-rotating

or rotating spindle.

- All screw jacks have oil lubrication as standard

- Maximized efficiency through optimized high-performance worm gear

- Available with ball or trapezoidal screw drive

- Can be mounted in any position due to the cubic design

Spindles – special spindles

Spindles are provided. In addition to

using the high-performance spindles, we are able to offer you an optimal

solution for all specific special applications. We design and implement your

system according to your wishes.

Lifting systems

Based

on our many years of experience in the development and construction of lifting

gears, we will be happy to design any specific system for you. Our range of

gears is ideal for quick deliveries, reliably and competently. We plan, develop

and design the complete system for you.

The gallery does not contain any images yet

Example of an aircraft maintenance facility.

Accessories | system components

We offer high-quality accessories for all gearboxes,

which are precisely selected for your installation situation. We are also happy

to manufacture special adaptations for you on request. Our standard accessories

include all units that supplement the gearbox and are necessary for the design

of the system.

- Footplates / Angle footplates

- Protective sleeve for spindle

- Special nuts

- Special material combinations

- Precision shafts for coupling gears

- Couplings and friction connections

- Cardan adapter further special fixtures

- Spindle protection

- Limit switches

- Lubricants for all applications

Repair and services

The quality of our gearboxes is an important part of our philosophy. We try to design our gearboxes according to the needs of our customers in such a way that we meet both the requirements for performance and economy.

For FLOHR, however, customer service does not end with the handover of the product. Each of our gearboxes is well documented and should give you a long service life. We also offer a full repair and maintenance service for all of our gearboxes.

In order to be able to provide any type of repair and service as quickly as possible, we offer our customers a well thought-out service strategy, which also includes the storage of special parts and a rolling exchange of strategically relevant parts. In conjunction with this, we offer a repair, maintenance and service for all of our customers' transmissions, irrespective of brand. With a quick and professional damage analysis, you will immediately receive a cost estimate for the necessary repair measures. After approval, we guarantee reliable processing of the repair or service order.

Thanks to our service strategy, we have already had very good experiences with our customers. Together with you, we agree on maintenance intervals in order to prevent damage and reduce downtimes to a minimum. However, should an unscheduled problem occur, you will be immediately supported by our team.

Talk to us about the service and maintenance concepts - we will be happy to support you with your planning!

Downloads

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de