News

-

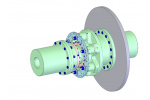

April 2024 Project presentation: Development of a special gearbox

Regardless of whether optimisation or new development is required. We work together with our customers to develop customised drive concepts. Supported by modern CAD systems, we plan, analyse and simulate the ideal drive solution at the highest level. In this project, our design team took on the development of a special gearbox for the maintenance of large compressors.

-

April 2024 Stainless steel safety couplings and friction torque limiters

In addition to reliable protection against overload and system failure, maintaining the operational capability of all drive elements also plays an important role, particularly in the most difficult environmental conditions of all drive elements plays an important role. Keyword: Corrosion protection

-

Februar 2024 Acoustic measuring device for ideal belt tension

With its highly sensitive sensor, the compact LüCo TensionPro2 measuring device enables non-contact, acoustic measurement of the belt tension. The professional measuring device enables precise adjustment of the belt tension. This increases the efficiency of the drive and reduces energy costs at the same time.

-

Januar 2024 New motor base for optimum belt tension for motors up to 200 kW

To optimise belt drives with larger electric motors, we can now offer the new MW 10 motor base series in addition to the MW 8 series. The maintenance-free motor bases ensure ideal belt tension and even torque transmission. In addition, oscillations, vibrations and load peaks are absorbed and belt wear is minimised.

-

Dezember 2023 We train specialists

Fabian (19) and Jan (16) have been the new trainees in our company since September. Three months after starting their training, both have settled into their everyday working lives and are actively supporting our teams in administration and production. We are once again looking for committed and motivated young people for an apprenticeship at FLOHR in the coming year.

-

November 2023 Case Study for modernisation of eRTG-cranes

Old installations often cause problems that outweigh the solutions they offer. The case study of our partner Johannes Hübner Giessen demonstrates how a fault-prone encoder system with a multitude of individual components can be transformed into a safe and low-maintenance system solution.

-

Oktober 2023 Energy-efficient safety coupling for container terminals

With increasingly rising energy costs, it is important for terminal operators to reduce energy consumption and thus save operating costs. The new Evolution Torque safety coupling from our partner Malmedie is designed for the Snag Overload System SOS and helps operators to achieve this goal.

-

Oktober 2023 Special solutions for shaft-hub connections

We are able to offer and supply a comprehensive range of clamping sets, shrink discs, mounting flanges, flange couplings and shaft couplings. We can also realise individual special solutions with short delivery times. State-of-the-art CNC production technology guarantees high-quality products.

-

Juli 2023 8 questions for the right choice of pneumatic grippers

The array of gripper choices in the automotive, pharmaceutical, electronics and consumer-goods industries for pick-and-place automation systems are numerous. The many gripper styles – all of which have their own size, method of operation, and required level of human interaction – is daunting. This leads to uninformed selections that fail to meet the needs of your application. It’s critical that you consider all variables before choosing your pneumatic gripper.

-

Juni 2023 New: Globoidal and parallel stepping gears

With the new globoidal and parallel indexing gearboxes, we have expanded our range of gearboxes for applications such as conveyor and slewing units, the automotive, food, packaging and consumer goods industries. These gearboxes are designed to support indexing applications that focus on starting and stopping a piece of equipment at precise intervals at set stations.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de