Stainless steel safety couplings and friction torque limiters

12.04.2024

In addition to reliable protection against overload and system failure, maintaining the operational capability of all drive elements also plays an important role, particularly in the most difficult environmental conditions of all drive elements plays an important role. Keyword: Corrosion protection

Our stainless steel couplings and overload systems offer solutions that go far beyond the usual range of applications. The torque limiters and couplings are ideal for use in industries such as the food, pharmaceutical and medical technology sectors.

The INOX series offer high quality and reliability at an attractive price-performance ratio.

Our product programme also offers stainless steel solutions in other areas: In addition to the mechanical production of drawing parts, a selection of clamping systems, couplings, friction connections and gearboxes is available.

Please do not hesitate to contact us or send us your enquiry right away. Our team will be happy to answer your questions and help you select the right product.

Downloads

Product overview

Safety couplings and torque limiters

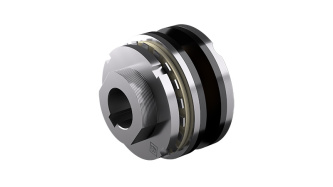

DF-SS Friction torque limiter made of stainless steel

Anti-slip clutch in which the transmission component is mounted between two friction rings and moves when the target torque is reached and shifts when the target torque is reached.

- Suitable for outdoor applications

- Slipping clutch model

- Made from stainless steel, fully machined

- Low-noise and vibration-free disengagement

- Simple torque adjustment

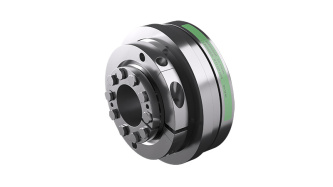

DSS/SG/N-SS Backlash-free torque limiter made of stainless steel*

High-tech safety clutch with balls, in which the movement is transmitted without torsional backlash. Device with high response sensitivity and immediate and precise disengagement.

- Suitable for the food, pharmaceutical and chemical industries

- Made from heat-treated stainless steel

- Compact, without torsional backlash

- Maintenance-free

* Negative version

Flexible couplings

GAS-SS Stainless steel star coupling

Flexible jaw coupling with strong vibration damping. Available with different types of fastening, elastic elements

different hardnesses and customised extensions.

- Standard version (GAS-SS) or with high torsional stiffness (GAS/SG-SS)

- Compact, easy to install

- Made of stainless steel, fully machined

- Various locking solutions (groove, clamp, etc.)

GTR-SS Torsionally stiff multiple disc clutch made of stainless steel

Torsionally rigid disc clutch with motion transmission without angular play and maximum flexibility of use. Available with personalised extension.

- Version with individual disc pack

- Made of stainless steel, fully machined

- Maximum torsional rigidity

- Various locking solutions (groove, clamp, etc.)

- Maintenance-free

GRI-SS Torsionally stiff coupling made of stainless steel

Torsionally rigid coupling that is particularly suitable for precise connections without misalignment between shafts.

- Version with clamp connection, 1-piece or can be dismantled into 2 parts

- Made of stainless steel, fully machined

- Very high torsional rigidity

- Maintenance-free

- Customised adaptation according to drawing

Friction connections / Conical clamping elements

We also have a wide range of stainless steel designs for friction-locked shaft-hub connections. In this area in particular, our connections are ideally suited to often difficult environments.

In addition to the standard sizes and designs, we also develop specifically optimised geometries and designs for our customers' applications.

The locking assembly connects the hub of a gearwheel, for example, to a shaft by means of a frictional connection. This backlash-free connection between the shaft and hub allows torques and axial forces to be transmitted reliably. Depending on the design of the locking assembly, high bending moments can also be reliably transmitted in addition to torques.

The displacement-controlled shrink discs are external clamping elements consisting of a pressure ring and a sleeve. By tightening the clamping screws with a specified screw tightening torque, the pressure ring is pulled axially onto the sleeve.

The torque-controlled shrink discs are an external clamping element consisting of a pressure ring and a sleeve. By tightening the clamping screw with the specified screw tightening torque, the pressure ring is pulled axially onto the sleeve.

Depending on the desired variant, a distinction is made between the three-part and the more compact two-part version.

While in the two-part version the pressure ring is clamped directly to the inner ring, the three-part shrink disc consists of two pressure rings (usually one with through holes and the other with threads) and a slotted inner ring.

- High resistance due to stainless, martensitic chromium steel 1.4122

- Very good wear resistance

- Good acid resistance and corrosion resistance

- Reliable transmission of torques even in difficult environments

- Nominal diameter from 14 mm to 240 mm / larger on request

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de