Friction connections and locking assemblies

Powerful shaft-hub connections

Our partner TAS Schäfer is a market leader in the production of mechanical and hydraulic friction-locked shaft-hub connections. In addition to mechanical shrink discs and clamping sets, the family-owned company is a global leader in the market for hydraulic shrink discs. The company's own state-of-the-art and certified production guarantees high-quality products. A customer-oriented, flexible and qualified team implements customer wishes quickly and professionally. Reliable technical advice from the design department is an essential component in this.

Product overview

-

Hydraulically tensionable products

Thanks to its fast and secure clamping, it is particularly suitable for assembly on test benches and repetitive clamping processes.

-

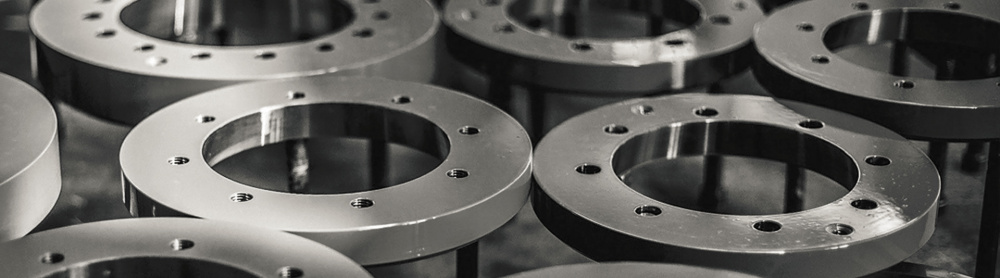

Shrink discs

Secure connection of shaft and hub by means of friction locking. Two- and three-part versions available. We would be happy to advise you on the ideal friction-fit connection.

-

Adapter flanges | Flange couplings

The external clamping elements can be used to connect disc-shaped attachments such as brake discs, cable pulleys and belt pulleys securely and backlash-free with a frictional connection.

-

Shaft couplings

Rigid and backlash-free connection of shaft ends. Compact design. Up to 1,513,000 Nm torque and mm shaft diameter. Customised special solutions possible.

-

Locking assemblies

Locking assemblies are used in mechanical engineering to create a frictional shaft-hub connection. The Locking assemblies connects the hub of a gear, for example, to a shaft by means of a frictional connection.

-

Stainless solutions

We offer customised shrink discs, clamping sets and shaft couplings made of stainless steel. Ideal for the chemical, food and packaging industries.

-

Special solutions

In co-operation with our design department, we are also able to manufacture special solutions for our customers, for example for flange adapters or shaft couplings.

Depending on the shaft-hub connection, the optimum clamping set solution is available. In addition to the shrink discs as a standard external clamping set, the range also includes shaft couplings and cardan shaft flange connections with the standardised DIN connections.

For the application-specific design of the shaft-hub connections, the catalogue data is available on demand. And if the standard is not enough, TAS Schäfer will be happy to develop the right solution specifically for your application.

Advantages at a glance

- Safe transmission for torques up to 18,000,000 Nm

- Suitable for shaft diameters from 8 mm to over 1,000 mm

- Fast, simple, space-saving assembly and non-destructive disassembly

- No fretting corrosion

- Compact design

- Normal surface finish of shaft and hub

- Can be used as application-specific assembly

- Can be clamped by screws or hydraulics

- State-of-the-art CNC machines and machining centres

- Own raw material stock ensures delivery capability

- 100% Made in Germany

Downloads

-

Shaft-hub connections - General overview

(26132 KB)

Shaft-hub connections - General overview

(26132 KB)

Large stock

For optimum delivery capability, we keep all essential diameters in stock for our customers as raw material - forged blanks. Despite the high capital commitment, we decided to take this step in order to ensure optimum availability even for special drive elements.

Advice on your optimal solution

Our frictional connections are considered state of the art. In particular, our various shrink disc models have long since established themselves in drive technology. They realise maximum energy density in the shaft-hub connection and are insensitive to shocks, impacts and corrosion. Therefore, they work absolutely reliably even under extreme conditions. Of course, we also recommend our range to you because we are convinced of its bandwidth. But if there is no perfect model for your individual application, we will optimise any shaft-hub unit using the latest design and calculation methods - until it meets your requirements 100%. Because customised solutions are our speciality.

All frictional connections are based on the same principle. In their simplest form, they consist of an inner and an outer ring with opposite conical surfaces. Axial displacement (mechanical or hydraulic) of the outer ring against the inner ring creates pressure. This causes the outer ring to expand outwards, while the inner ring is compressed inwards. The existing friction of the pressure occurring between the hub and the shaft means that a torque and/or an axial force can be transmitted. These depend on the coefficient of friction, the fit clearance, the clamping length and the shaft diameter.

Areas of application - Examples of use

Friction lock connections are versatile and can be used in almost all drive trains as well as in many other applications. Element sizes range from a few mm to more than 1,000 mm, with transmission torques from a few Nm to more than 18,000,000 Nm.

Wind power

Our hydraulic or mechanical shrink discs are used worldwide for the

connection of the hollow shaft of the transmission with the rotor shaft.

Materials handling

In the powertrain of conveyor belts, our flange couplings are also used.

Our shrink discs and locking assemblies are used in the field of

conveyor technology, especially in heavy-duty cranes, conveyor drums,

elevators and storage technology.

Drive technology

Our mechanical shrink discs are used for driving cable winches. In

addition, hydraulic shrink discs, flange couplings and locking

assemblies are used for shaft connections, motor connections and

brake discs.

Wood processing

Our shrink discs are installed in wood processing machines. A typical

applictaion is the wood transport within the maschine. Depending on

customer requirements, shaft couplins, locking assemblies and flange

couplings are also used in this branch.

Paper industrie

Our locking assemblies are woldwide installed in different packaging

machines. For example, they are used to mounting pullys and also for the

transport of goods in the machines. Furthermore, shrink discs and shaft

couplings are also used in this industrie.

Packaging machines

Preferably, our hydraulic shrink discs are used in this insutrie, this

allows faster replacement of rolls. Furthermore, mechanical shrink discs

and locking assemblies are installed in rollers and winding machines.

Mining

Different versions of our flange coupling are used in bucket wheel

excavators. Furthermore, our locking assemblies and shrink discs are

used in conveyor drums, stirring shaft connections and crushers.

Marine technology

Our hydraulic or mechanical shaft coupling drive rudder an shaft

systems. Furthermore, our hydraulic and mechanical shrink discs are used

to connect intermediate shafts and thrust bearing connections.

Hydropower

Our connections flanges are mainly installed in hydropower plants.

Our

locking assemblies find their application in hydropower technology,

e.g. in Francis turbines. Especially, the stainlees steel versions have a

great importance in these applictaions.

Oil and gas industrie

Especially our stainlees steel products are designed for extreme

conditions. Shaft couplings are used to connect gearboxes and motors.

For sealing systems on pumps, our shrinks are also used.

Food industrie

Stainless steel products are standard in the food industrie. For this

reason, our stainlees steel shrink discs or locking assemblies are

essential for the high hygienic standatds of this industrie. Typical

applications are stirring systems, ice machines and filling machines

Gearbox test benches

Our hydraulic shrink discs, especially for gearbox test benches, are

designed and manufactured to customer specifications. Through our years

of know-how, we are world market leaders in this industrie and equip

test benches worldwide with our products.

Effect through tensioning and pressing

In a frictional connection, components are held together by static frictional forces in which they are axially braced against each other by conical friction surfaces. The radial pressure creates the bodies of the connection that are elastically braced in the direction of the shaft. The at least two bodies are moved axially against each other by screws, whereby the interference fit transmits ever greater radial forces through the surface pressure. The friction force generated opposes the displacement forces acting from the outside.

The special feature of the shaft-hub connection is the pure frictional connection. There does not have to be any weakening of the shafts to be connected in order to transmit the torque. Decisive for a reliable connection is the quality of the components used in terms of both material and workmanship. The connections are used wherever forces are to be introduced or torques transmitted and quick and easy assembly and disassembly are required. Friction connections can be found, among other things, in winches, various energy systems, in ship drives, in conveying and crushing technology in rolling mills and everywhere where torques have to be reliably transmitted.

An extremely powerful connection

A frictional shaft-hub connection from the field of mechanical engineering is also called a clamping set. In practice, you have to imagine that a machine element connects a hub, which can be a gear wheel, for example, with a shaft so that a torque and axial forces can be transmitted between these two elements without a form fit. At the same time, the hub is secured against axial displacement on the shaft.

Various technical designs

A distinction can be made between self-centring and non-centring clamping sets. Self-centring clamping sets are able to centre a hub on a shaft with a high degree of accuracy and thus ensure correspondingly good concentricity. If non-centring clamping sets are used, a sufficiently long centring between a shaft and a hub is necessary, which should be at least twice as long as the width of the clamping set. The advantage of non-centring clamping sets is that they have the ability to compensate for larger differences in fit between a shaft and a hub.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de