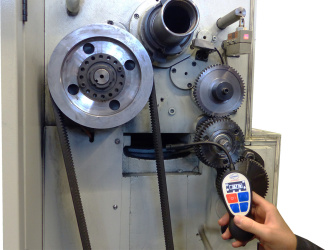

Acoustic measuring device for ideal belt tension

12.02.2024

With its highly sensitive sensor, the compact LüCo TensionPro2 measuring device enables non-contact, acoustic measurement of the belt tension. The professional measuring device enables precise adjustment of the belt tension. This increases the efficiency of the drive and reduces energy costs at the same time.

The new LüCo TensionPro2© makes it possible to measure the appropriate belt tension quickly, easily and accurately. The fully electronic belt tension measuring device is equipped with the latest microprocessor technology and can be used for V-belts, timing belts and power transmission belts. Reliable measurement results are achieved regardless of the type and condition of the drive belt.

The acoustic measuring principle is utilised: An impact impulse (e.g. by hand or a suitable tool) is transmitted to the belt. This initially vibrates in all vibration modes. However, the high-frequency vibrations decay faster than the basic vibration.

The vibration frequency of the fundamental vibration is measured in Hertz (Hz) and is in a fixed relationship with the belt pre-tension. This means that the higher the frequency of a belt, the higher its tension. The type and condition of the belt have no influence on the measurement result.

Your advantages

- Highly sensitive sensor for precise measurement of belt tension

- Ergonomic shape for optimum one-handed use

- Small sensor head on the flexible gooseneck for measurements even in hard-to-reach places

- Integrated, rechargeable lithium polymer battery

- Additional functions via app use

- Suitable for all belt and tension member types

- Measuring range: 10 - 600 Hz

Downloads

-

Measurement technology for drive belts

(2985 KB)

Measurement technology for drive belts

(2985 KB)

-

Operating instructions LüCo TensionPro2

(1857 KB)

Operating instructions LüCo TensionPro2

(1857 KB)

That's why you should check the belt tension regularly

Precise pre-tensioning favours the service life of the belt drive and prevents overloading of the drive components. Only a perfectly adjusted belt drive can achieve efficient performance.

- If the belt tension is too high, the roller bearings and timing belt flanks are subject to increased wear. The service life of the drive components is shortened and costs increase.

- If the belt tension is too low, the required power cannot be transmitted. The belts vibrate, flutter or belt teeth are skipped. The slipping of the V-belts is also noticeable acoustically. In addition, heavy wear on the belts is recognisable.

Precisely measuring and adjusting the belt tension extends the service life of the pulleys, belts, bearings and seals in the long term and prevents the drive from being overloaded. The level of vibration is reduced.

We generally recommend investing in professional measurement technology, especially when using higher-quality industrial belts. Using TensionPro2 increases the efficiency of the belt drive and reduces energy costs at the same time. The belt tension tester pays for itself within just a few months.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de