Energy-efficient safety coupling for container terminals

24.10.2023

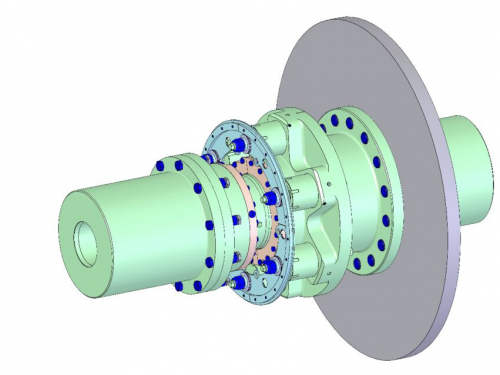

With increasingly rising energy costs, it is important for terminal operators to reduce energy consumption and thus save operating costs. The new Evolution Torque safety coupling from our partner Malmedie is designed for the Snag Overload System SOS and helps operators to achieve this goal.

Compared to previous designs, the company was able to reduce inertia of this technology by more than 45% and mass by about 20%. Acceleration and deceleration of inertia are proportional to power consumption in drivetrains. Safety coupling are accelerated to top speed and decelerated to a full stop twice for each container being moved. Energy savings are thus significant.

Reducing inertia of the coupling means that all components in the powertrain will see smaller mechanical loads. Reducing the “mechanical footprint” of the coupling will therefore help to choose other smaller components, saving initial investment cost and resulting in additional inertia-related energy savings.

Dr. André Voßnacke, head of technology Malmedie: “We looked at aviation to inspire our lightweight designs. We challenged our assumptions on what customers value. The team is proud of the result.”

Additional features realized in the Evolution Torque Safety Coupling include easy maintenance access and low wear part count and cost. The system needs to be serviced once every 3 years.

The Evolution Torque Safety Coupling is integrated into the drivetrain of the main hoist in ship-to-shore container cranes. Here, they prevent catastrophic outcomes of snag-events and protect the drivetrain and the structure of the crane from overloads. Importantly, the Evolution Torque Safety Coupling does so purely mechanically and ultra-fast, without the need of hydraulics or electric circuitry. Alternative snag-prevention systems rely on signal analysis and processing and therefore need order of magnitudes longer to react. In a world of increasing automation, a mechanical snag-prevention-system is an important contribution to ensure safety while humans are supervising loading operations from afar or not at all.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de