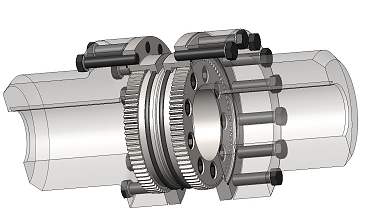

Gear coupling, gear joint spindle

Gear couplings are designed with crowned teeth and are used where torque must be transmitted with shaft connections that can move freely in three dimensions (angular, radial and axial). FLOHR has its own range of gear couplings for standard industrial applications. The program is supplemented by high-performance couplings from MALMEDIE Antriebstechnik GmbH. FLOHR uses the outstanding quality of the MALMEDIE coupling both in its own systems and as a sales partner for MALMEDIE Switzerland and MALMEDIE Austria.

With more

than 50 years of operating experience using gear couplings within drive

technology, this then speaks for the high performance and quality of the

coupling units. The gear couplings can compensate for angular, radial and axial

deviations. With the standard toothed coupling, the misalignment capability is

±0.75° per coupling half, special versions can be supplied up to ±5°.

Downloads

-

FLOHR Zahnkupplungen

(915 KB)

FLOHR Zahnkupplungen

(915 KB)

-

Malmedie gear couplings

(1508 KB)

Malmedie gear couplings

(1508 KB)

-

Anfrageformular Zahnkupplungen

(312 KB)

Anfrageformular Zahnkupplungen

(312 KB)

Applications

- Hot- and Cold Rolling Mills

- Roller Conveyors

- Coiler / Uncoiler Drives

- Levelling Machines

- Shears

- Ship Drives

- Cement Machines

- Cranes

- Crushers, Mixers

- Briquetting Machines, Shredders, General Engineering

The MALMEDIE gear coupling range offers a large number of variants, so that an optimal solution can be found even for difficult and / or critical applications.

-

Gear couplings GLX

The gear coupling GLX is easy to mount / dismantle due to the two-piece housing. At the same time, the distance between the two gears planes is more, allowing more radial compensation.

-

Gear couplings LX

The Gear-Coupling LX is compact due to the single-piece housing. Ideal for applications with space restrictions.

-

Gear joint spindles GZ

MALMEDIE gear joint spindles are always optimally matched to a very wide variety of customer requirements. Particular attention is paid here to the rapid replacement of worn parts.

Advantages

- Suitable for reverse operations

- Quiet running due to head centering

- Special design for vertical operation available

- Large permissible finish bore

- Easy replacment of seals with split cover

- High level of operational reliability due to high Quality materials

- Long service life with low levels of maintenance

- High ambient temperatures possible

- Interchangeable with preceding series

Overriding characteristics

- Economic efficiency with high performance

- Higher load capacity compared to the competition

- High permissible torque within a small installation space

- High number of variants for complex applications

- Compensation of angular, axial and radial deviations

- Long service life

- Freely movable shafts on both hub and housing

- Automatic wear

indicator option also available

- Suitable for use in hazardous

areas according to RL 94/9/EG

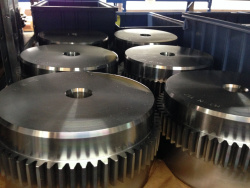

Quality and production of gear couplings

All gear

coupling parts are manufactured according to strict internal quality

procedures. Modern CNC manufacturing technology ensures the interchangeability

of individual parts. All power-transmitting clutch parts are made of

high-quality heat-treated steel. In special cases, it is possible to increase

the performance of the gear coupling or reduce wear through the targeted

selection of materials and appropriate hardening processes. Professional and

experienced installation and alignment of the coupling is also crucial. We

would be happy to support you with any questions on this topic.

Structure and characteristics

The

coupling hubs with crowned external splines run in housings with straight

internal splines. This allows the coupling hubs to to have a three dimensional

movement in the housings and compensate for angular, radial and axial

deviations of the shafts to be connected. For standard gear couplings, the

misalignment capability is ±0.75° per coupling half, special designs can be

supplied up to ±5°.

Wear indicator

The

optical wear indicator ensures that the wear of the coupling can be checked.

This enables simple and safe monitoring of the units during operation, which

reliably protects against failure. A sudden shutdown is avoided and the

maintenance intervals by the experienced MALMEDIE team are reduced to a minimum

downtime.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de