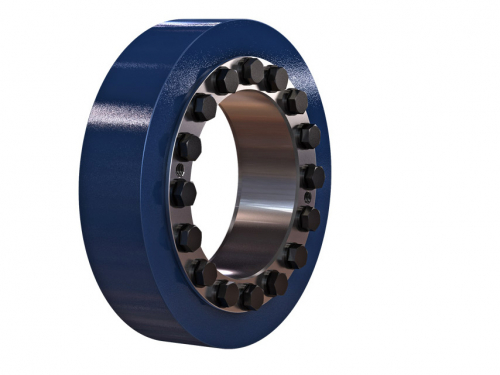

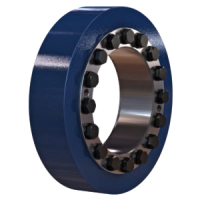

2-part shrink discs (torque-controlled)

The 2-part shrink disc (torque-controlled) is an external clamping

element consisting of a pressure ring and a sleeve. By tightening the

clamping screw with the specified screw tightening torque, the pressure

ring is pulled axially onto the sleeve. By using conical surfaces, the

inner diameter of the sleeve is reduced so that a radial clamping force

is applied to the hollow shaft.

The clamping force applied by the shrink disc connection creates a

frictional connection at the contact surface between the shaft and hub.

Compared to the 3-part shrink disc, the 2-part shrink disc has a smaller

cone angle and a self-locking function. Due to the small cone angle,

the sleeve has additional push-off threads which allow the pressure ring

and sleeve to be pressed apart during disassembly.

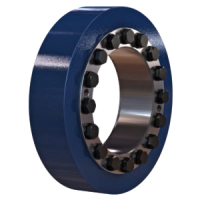

This shrink discs do not have a defined clamping travel. This enables

them to compensate for a larger fitting tolerance during assembly. The

clamping screws of the 2-part shrink disc (torque-controlled) are

tightened evenly in sequence until the specified screw tightening torque

is reached. When this assembly condition is reached, it is ensured that

the torques specified in the catalog can be transmitted. 2-part shrink

discs (torque-controlled) are available in various designs.

The benefits

- Compensation of an increased fitting clearance

- Different designs and special surface finish possible

- Transmittable torque from 36 Nm to 3,356,000 Nm

- Nominal diameter from 14 mm to 660 mm

- Easy assembly and disassembly

Product overview

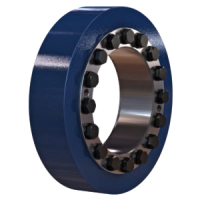

Standard-Series

(3171)

Standard-Series strenghtened

(3181)

Heavy Series

(3191)

Heavy Series strenghtened

(3193)

The 2-part shrink discs (torque-controlled) can generally transmit the

same torque as 3-part shrink discs and differ only in their design. Die

zweiteilgen Schrumpfscheiben gibt es in

verschiedenen Ausführungen. The two-piece shrink discs are available in

various designs. Depending on the installation space available to you,

the required torque or special environmental requirements, we will find

the right solution for you together.

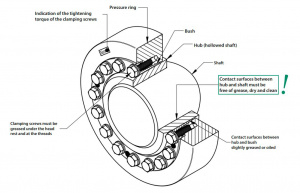

Assembly

It is installed by sliding the shrink disc onto the hollow shaft and the subsequent tightening of the screws. By using conical surfaces the inner diameter reduces and the radial pressure is built up. The 31xx range of shrink discs are self-locking. The clamping forces are provided and controlled through the screws (force controlled). This allows the direct compensation of the clearance between the shaft and hub, without an overload that may occur on path controlled shrink discs, due to small or over sized clearance. Except for this are the shrink disks of the type 3173 as well as the types 3191 and 3193 to d 185 mm. They are controlled by path (front faces are flush).

To achieve proper operation

with a sufficiently high coefficient

of friction, the contact surfaces

between shaft and hub must be

dry, clean and free of grease. The

functional surfaces of the shrink disc,

the thread and head rests of the

screws, are equipped at the factory

with lubricant. Molykote G-Rapid

Plus or comparable must be used

as a lubricant. The contact surfaces

between the hub and the bush must

be provided with grease or oil before

installation. The supplied shrink discs are ready

for installation.

Application examples

As standard, 2-part shrink discs are used in the same way as 3-part shrink discs in the entire area of frictionally engaged shaft-hub connections, e.g. in drive technology, the oil and gas industry, the wood industry or hollow shaft gearboxes.

Other areas of application are, for

example wind power, drive technology, raw material extraction, conveying

technology, crushing technology, mixing and process technology as well

as on hollow shaft gearboxes of all makes.

Flohr Industrietechnik GmbH - Im Unteren Tal 1 - D-79761 Waldshut-Tiengen - Phone: +49 (0)7751 / 8731-0 - info@flohr-industrietechnik.de